LOAD RUNNER

HOME

LOAD RUNNER

HOME  Load Runner

Load Runner

New Starts with LOAD RUNNER

Doota Industrial America, LLC(hereinafter "Doota Industrial") has begun its business since 2011 to deliver steel outfitting for Shipbuilding and mainly Offshore industries. Doota Industrial has lately launched Load Runner which is an eco-friendly modular support channel to satisfy customers’ requirements along the latest global trend in various industries.

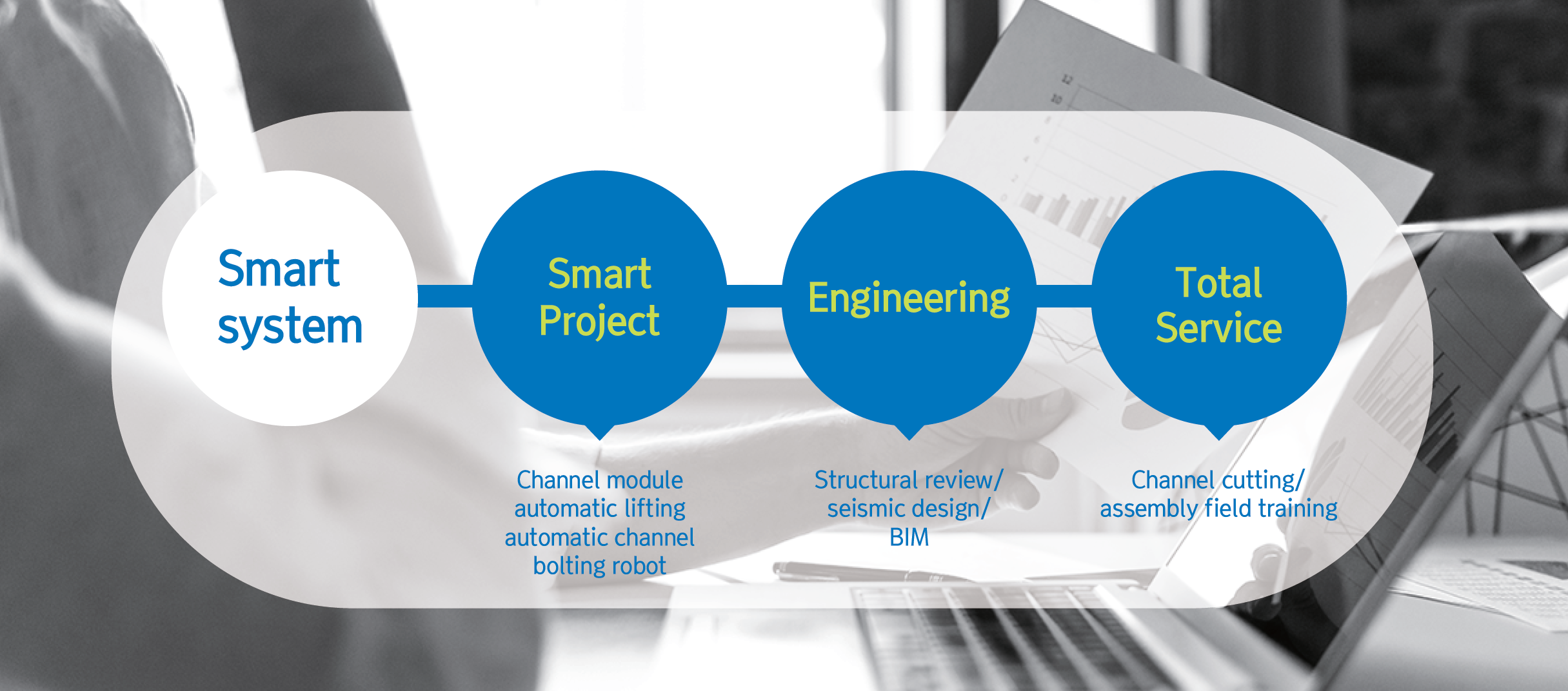

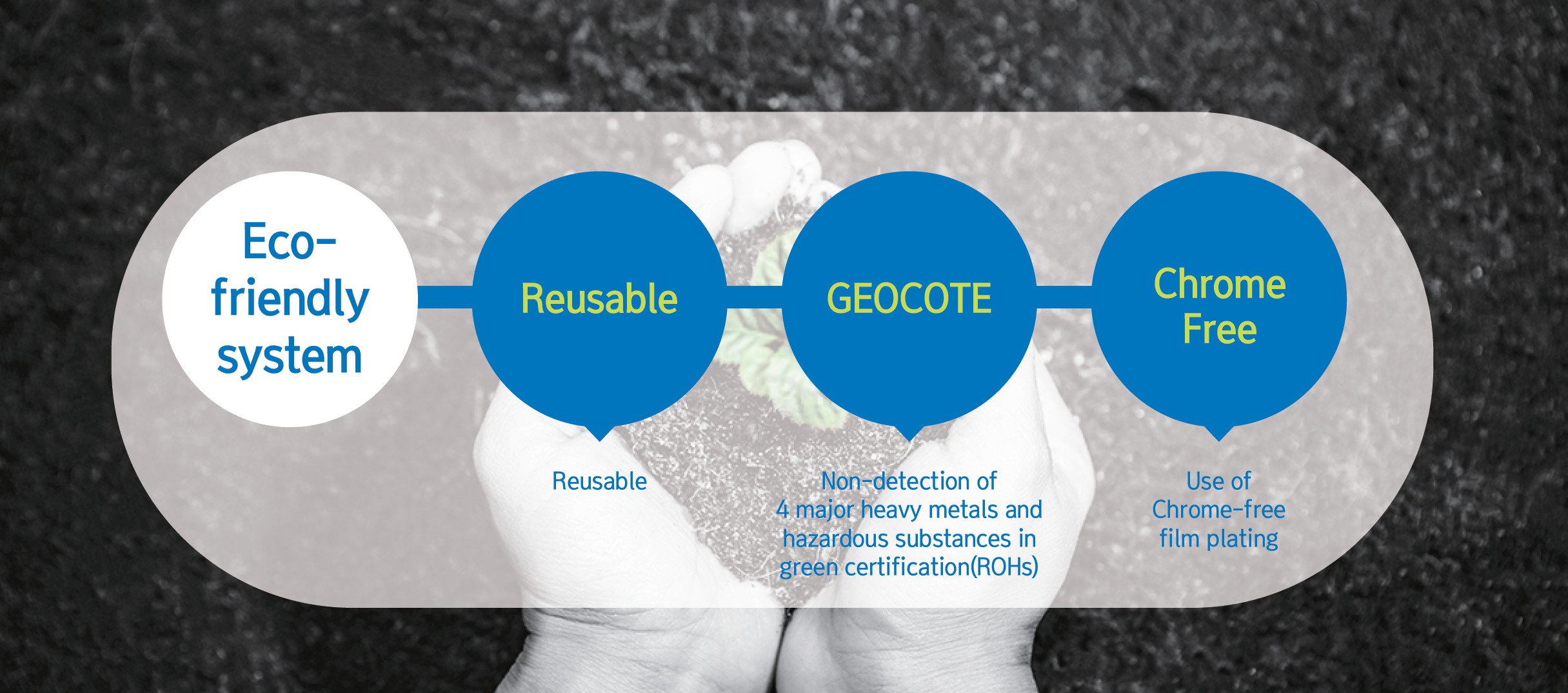

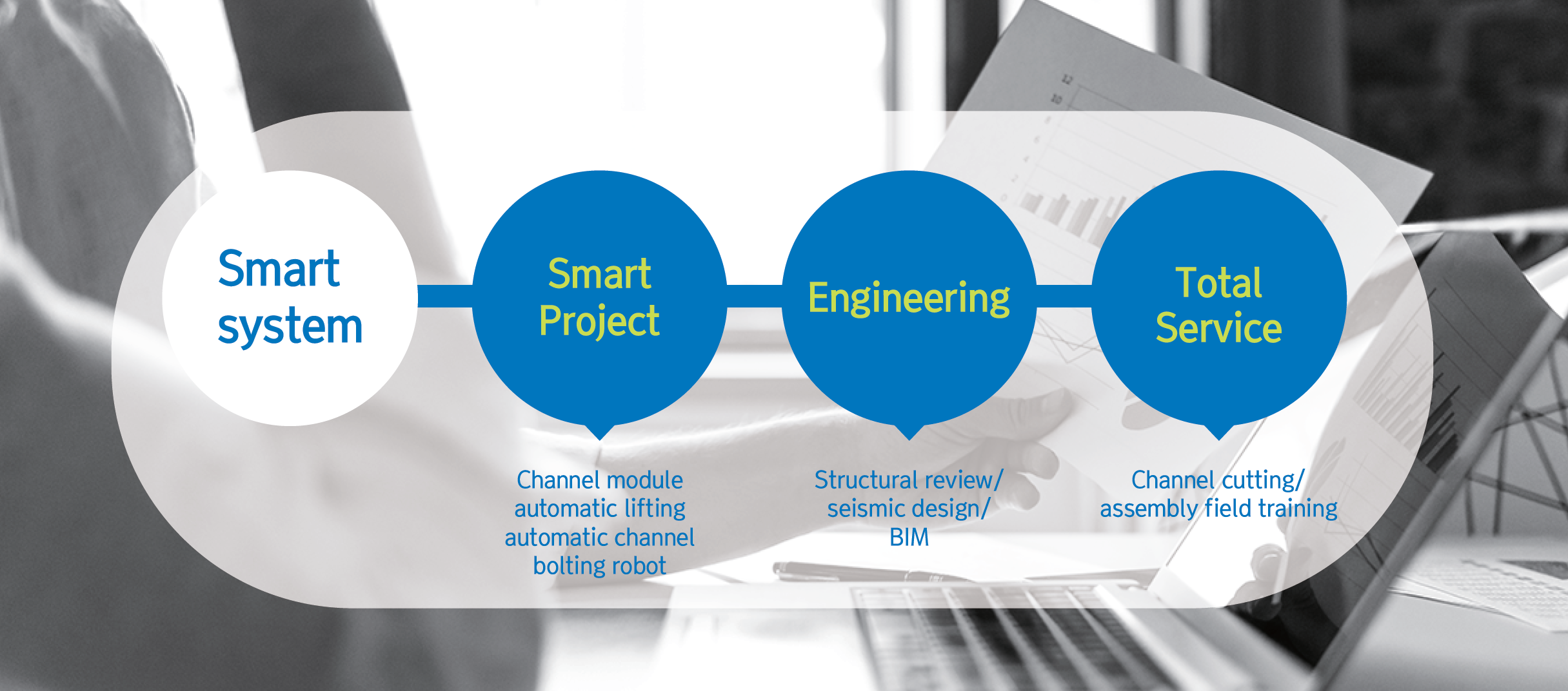

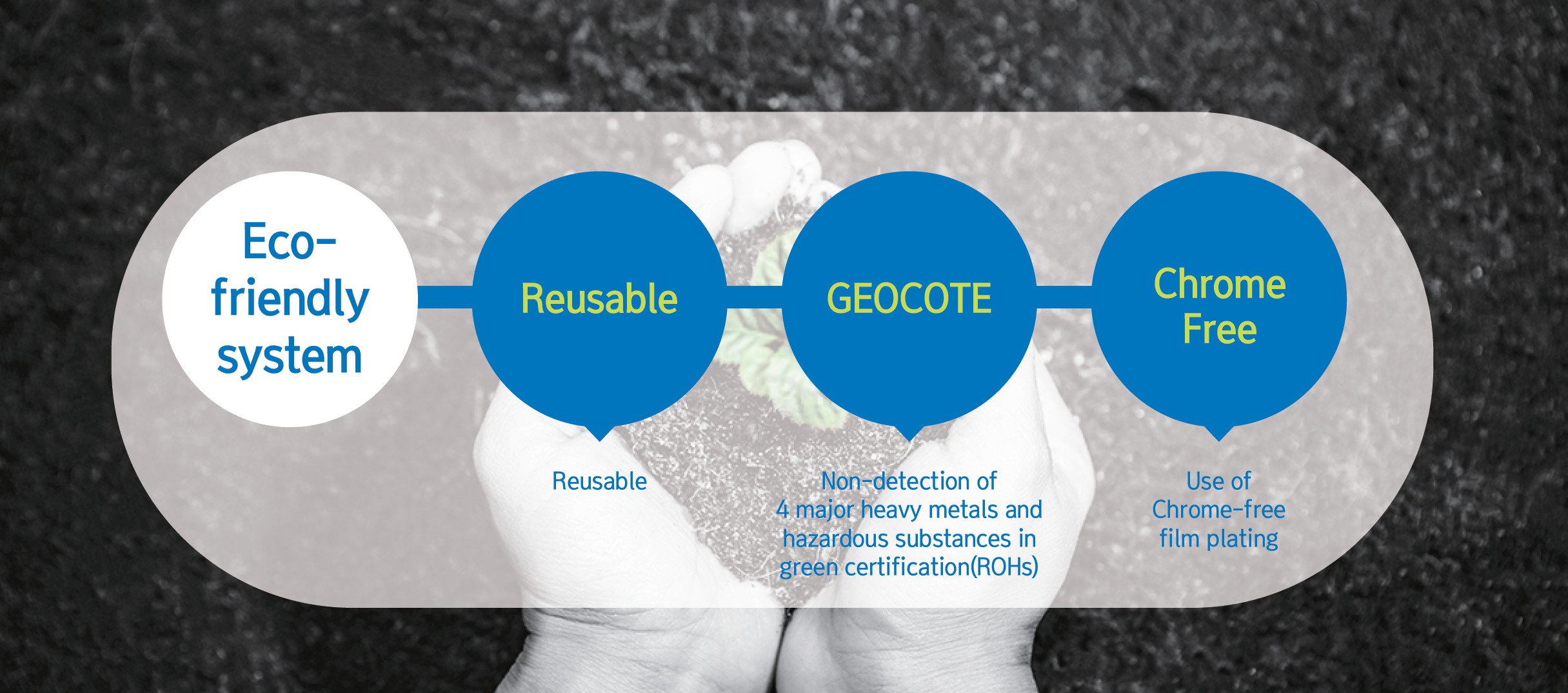

Load Runner is based on PosMAC steel and GEOCOTE coating so, reusable and eco-friendly. Doota Industrial supports customers by offering total service including cutting, pre-assembly, engineering and seismic design review. In addition, Doota Industrial pursues maximization of field productivity and safety through its own differentiated Smart Project Management with utilization of channel lifting AGV and collaborative robot for automated bolting.

Doota Industrial has delivered not only basic U shape but also custom-made support, racks, stands and various kinds of accessories to meet requested delivery time and eventually make no delay on construction progress. Doota Industrial pursues sustainable growth and put ur efforts into satisfying customers' requirements from diverse industries including Offshore,LNG vessel, Petrochemical refinery, Wind·Thermal·Solar power plant, Microchip factory, Data center etc.

Environment & Smart Modular system

Environment & Smart Modular system

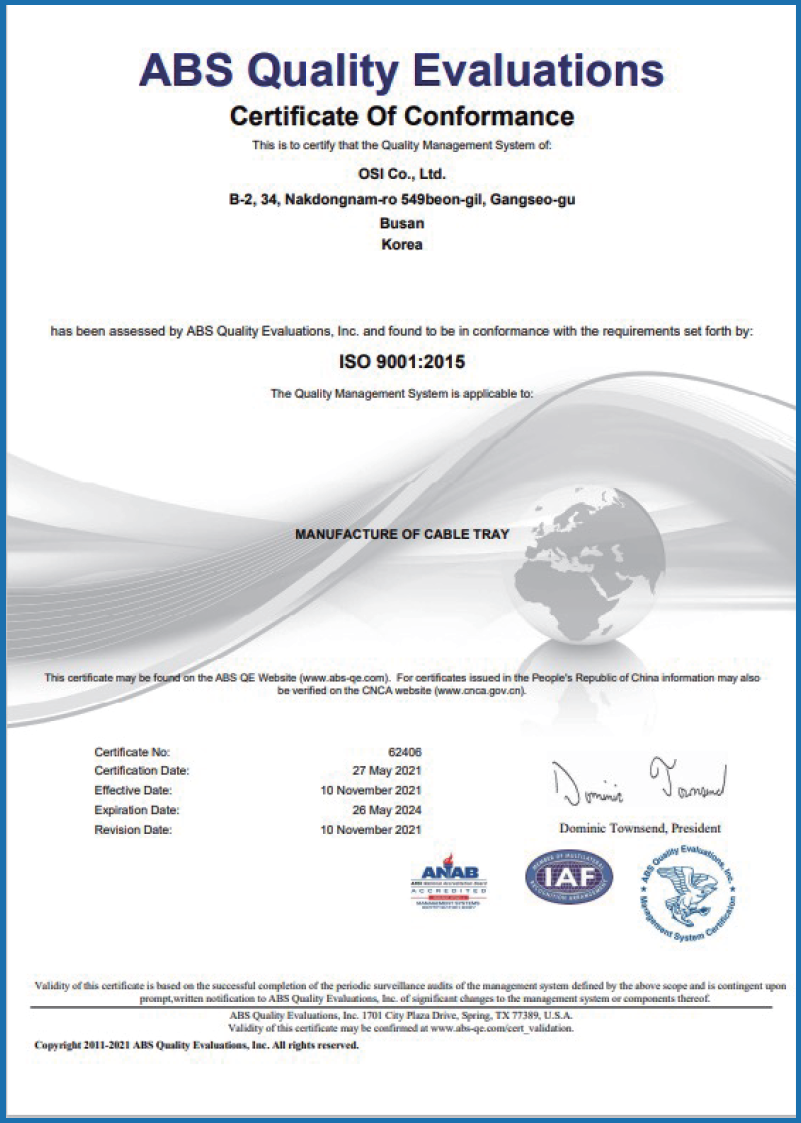

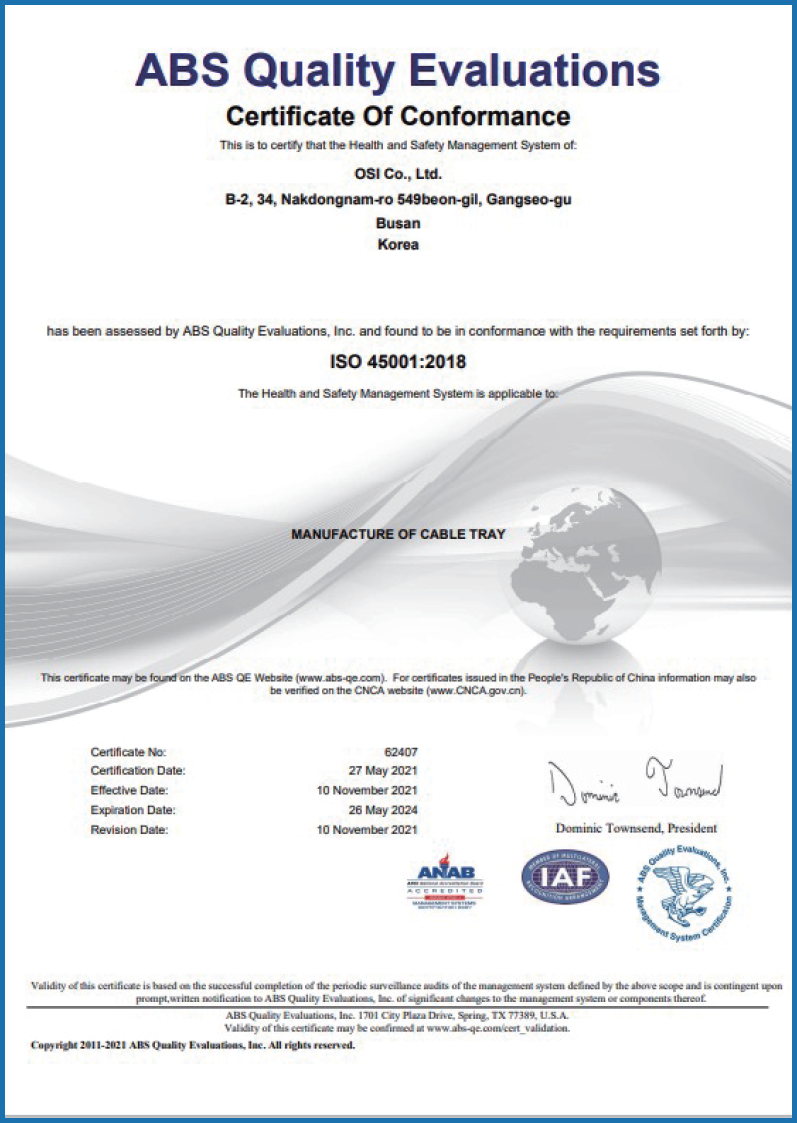

CERTIFICATE

Acquiring the international quality standard ISO 9001, ISO 14001, and ISO 45001, we have maintained high level of Quality and HSE management.

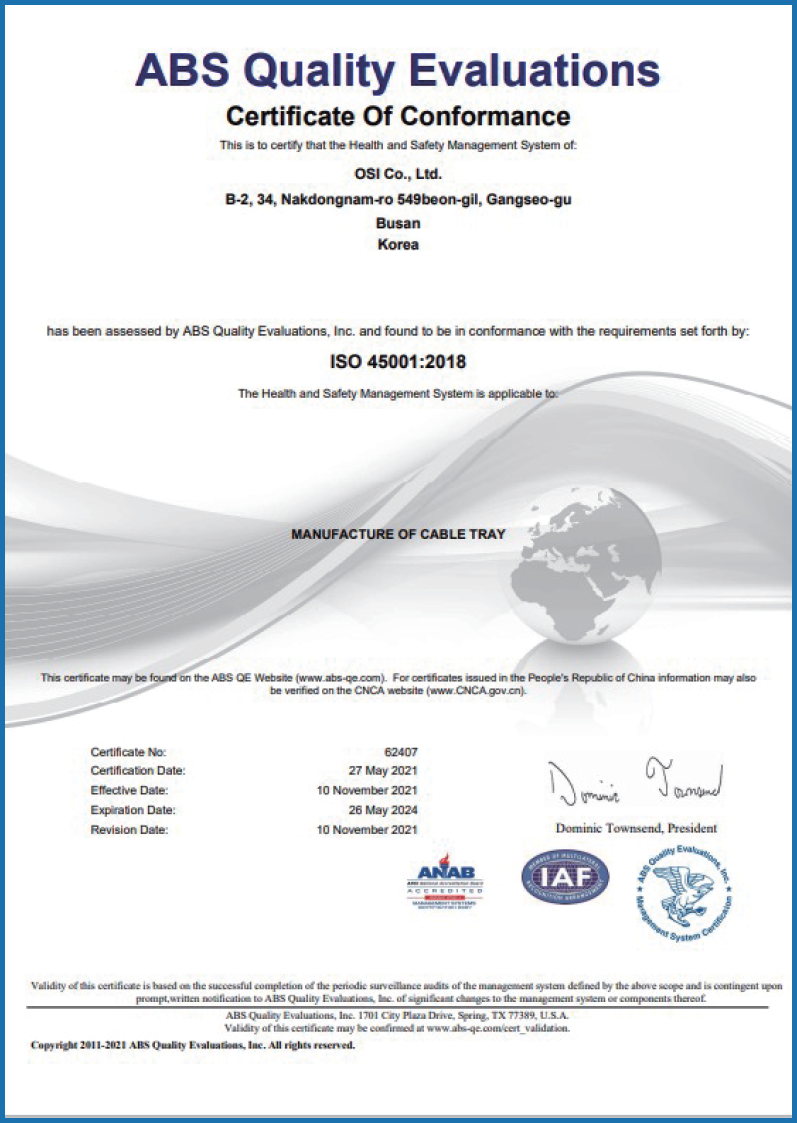

FACTORY

Our partner company OSI is located in Busan and Yangju, South Korea.

Busan

Yangju

Yangju

EQUIPMENT

We are maximizing production efficiency with the latest equipment and innovative technology.

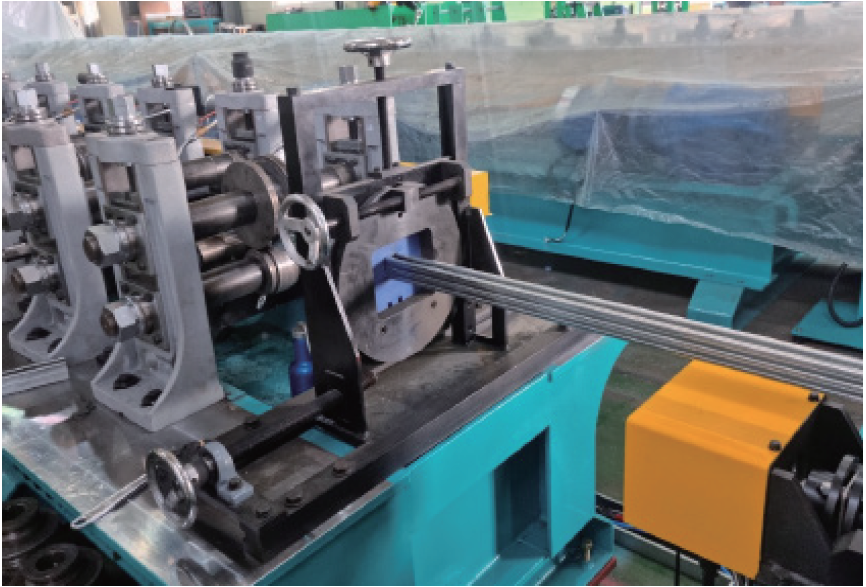

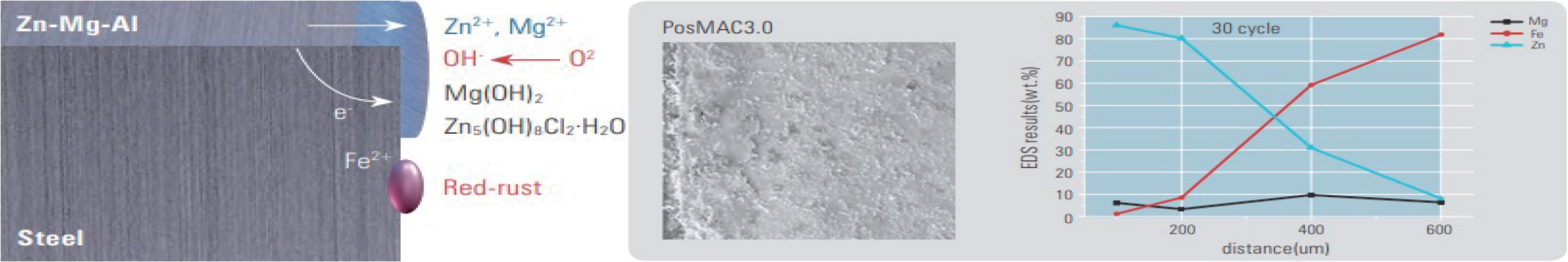

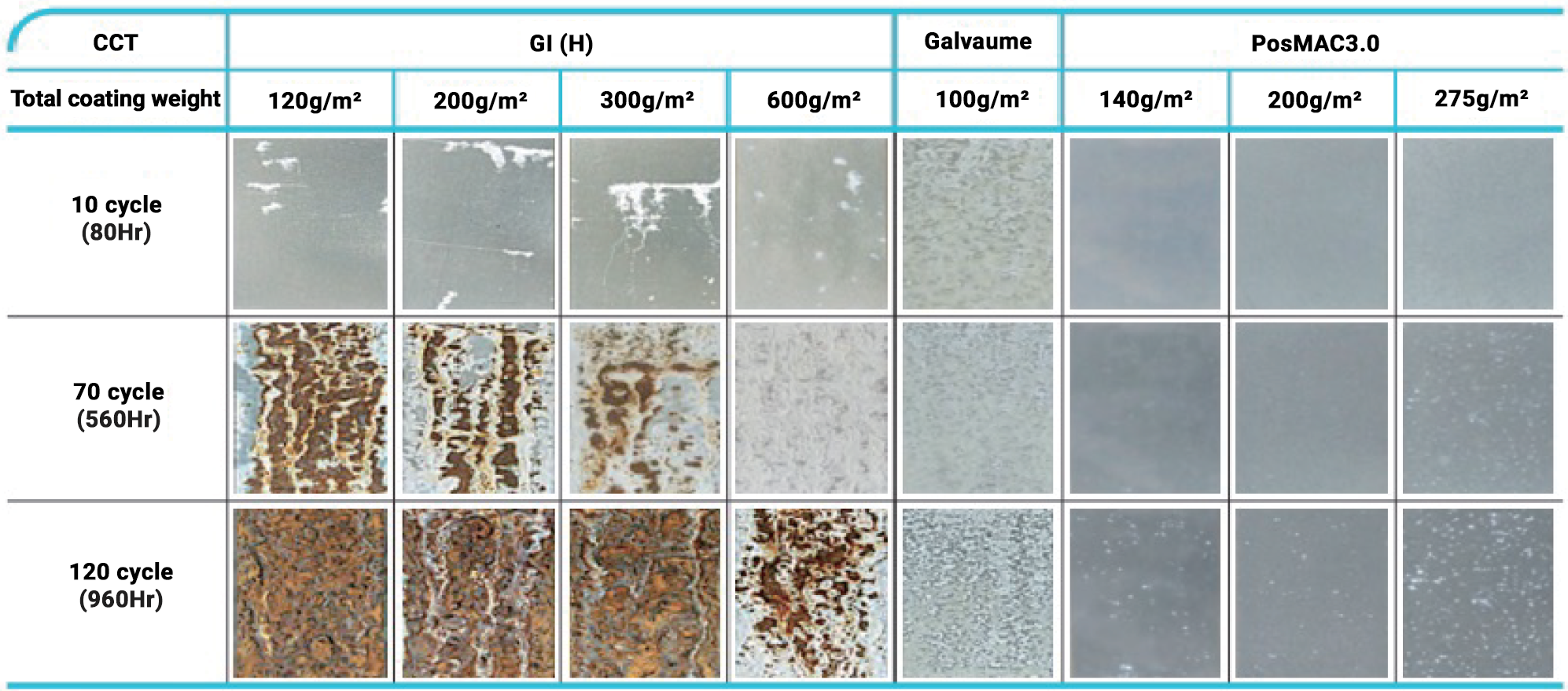

PosMAC 3.0 Corrosion resistance test

Our products boast excellent corrosion resistance by using PosMac3.0.

Comparison of corrosion resistance of

flat panel with Hot dip galvanizing(GI(H)), posMAC3.0, and galvalume (CCT)

- PosMAC 3.0 panel shows 5~10 times stronger corrosion resistance than the hot dip galvanized panel.

- Also, PosMAC 3.0 shows an equivalent or higher level of corrosion test compared to galvanizing.

- (CCT, Cyclic Corrosion Test)

[ISO 14993] 1Cycle : Applying salt spray 2Hr(5%%NaCl, 35%) → Dry 4Hr(25%RH, 60 °C) → Moisturizing 2Hr(95%RH, 50°C)

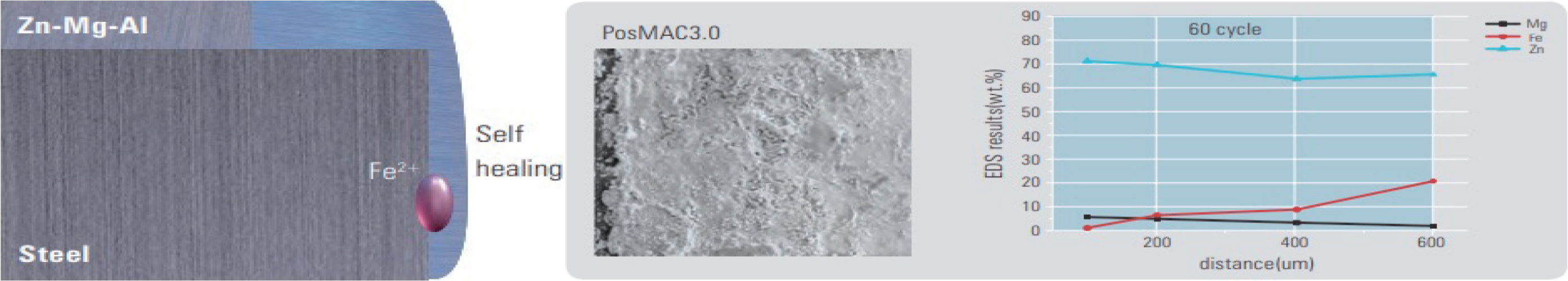

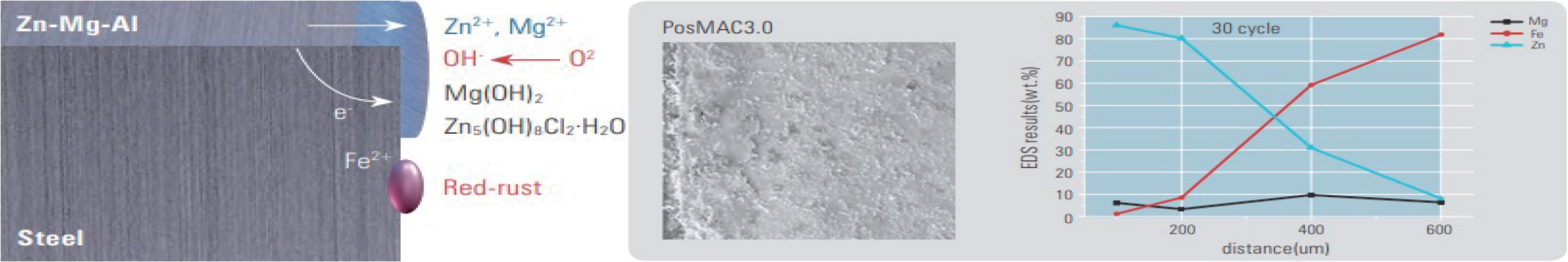

PosMAC 3.0 Corrosion resistance of sheared edge

When a sheared edge occurs, the upper plating layer melts to cover the cross-section and promotes the growth of

stable corrosion products. However, red rust will occur on the already exposed steel plate. After that, if the sheared

edge is coated with a film of corrosion products, it prevents the corrosion of the cross section.

PosMAC 3.0 Corrosion resistance of sheared edge

When a sheared edge occurs, the upper plating layer melts to cover the cross-section and promotes the growth of

stable corrosion products. However, red rust will occur on the already exposed steel plate. After that, if the sheared

edge is coated with a film of corrosion products, it prevents the corrosion of the cross section.

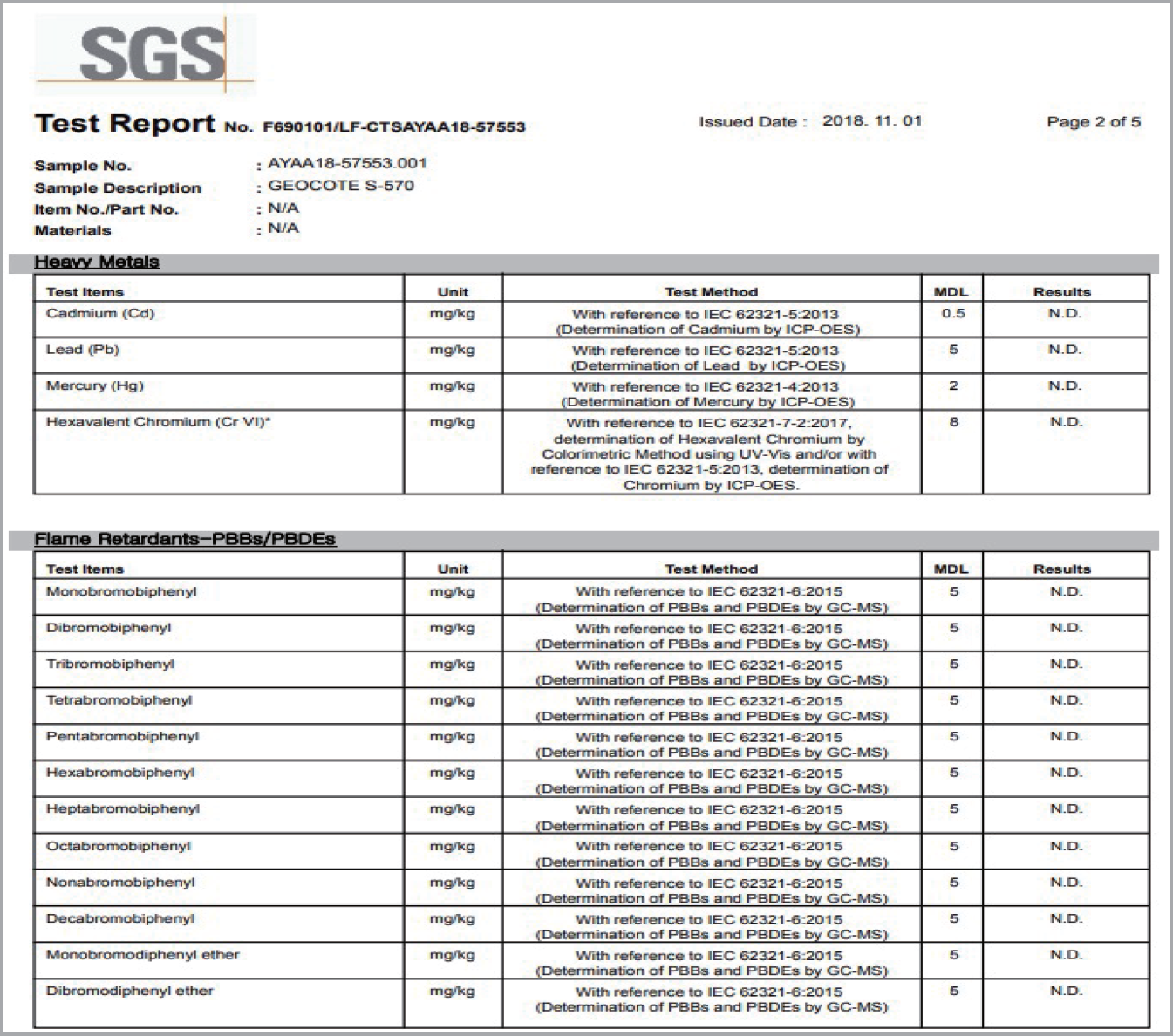

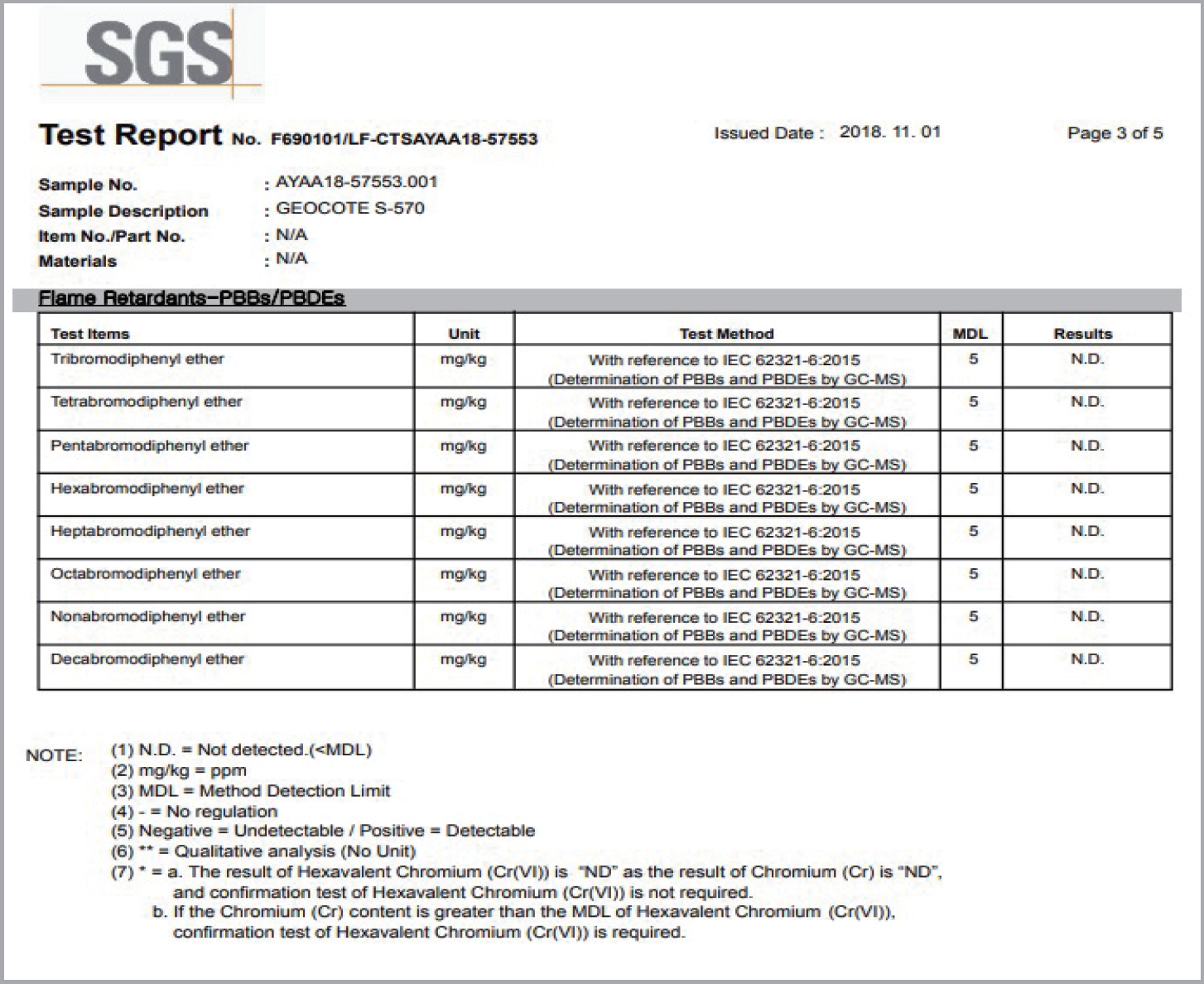

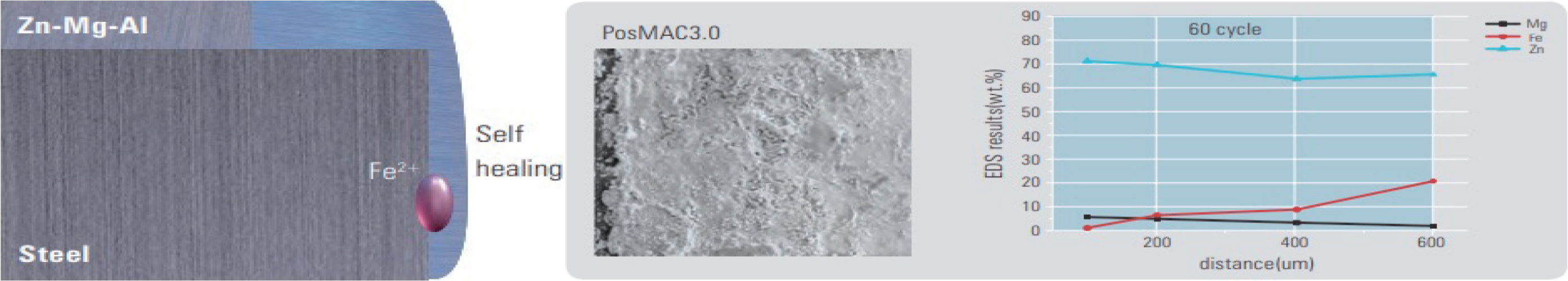

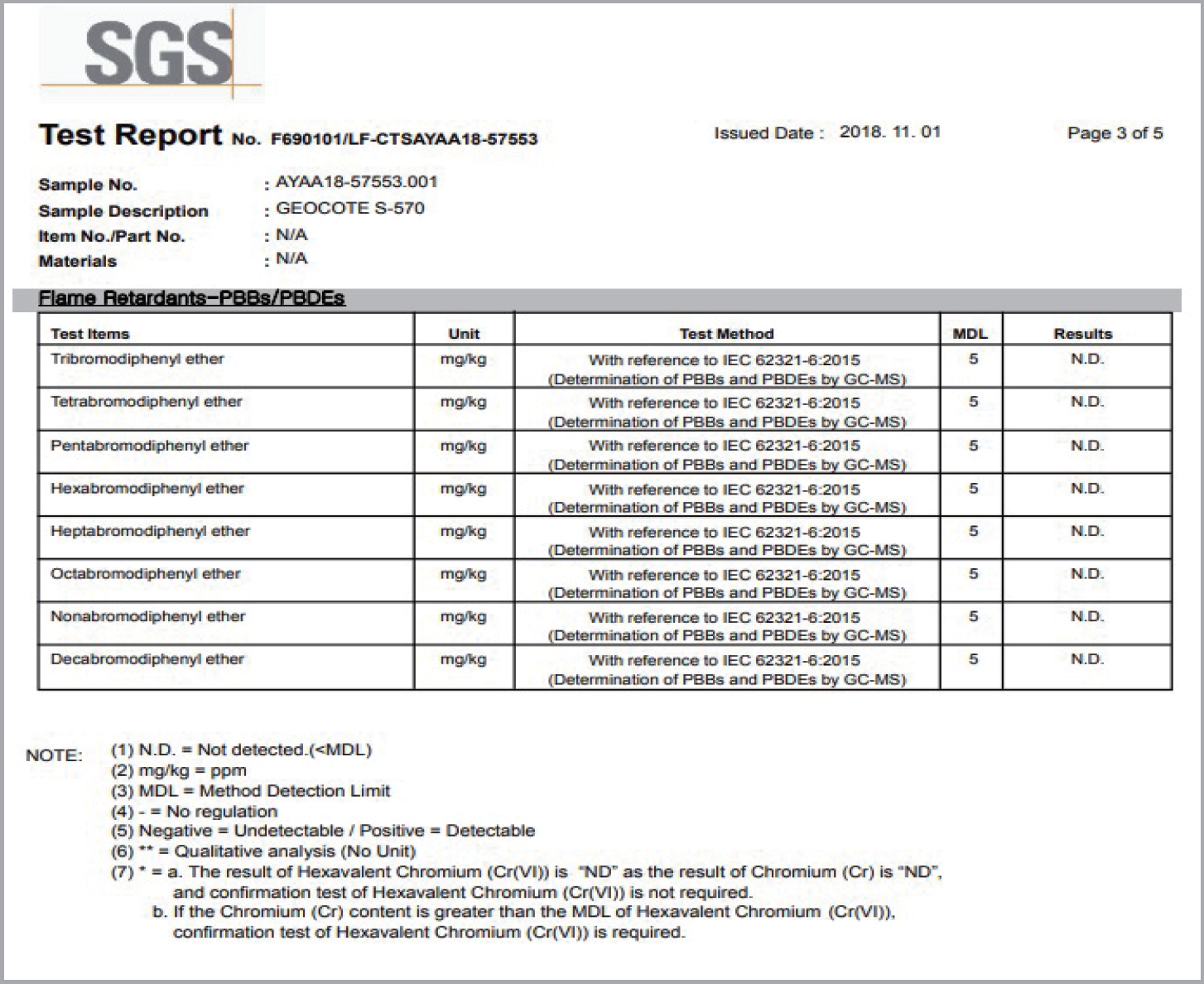

GEOCOTE test report

Accessories(Bolts, Connectors)

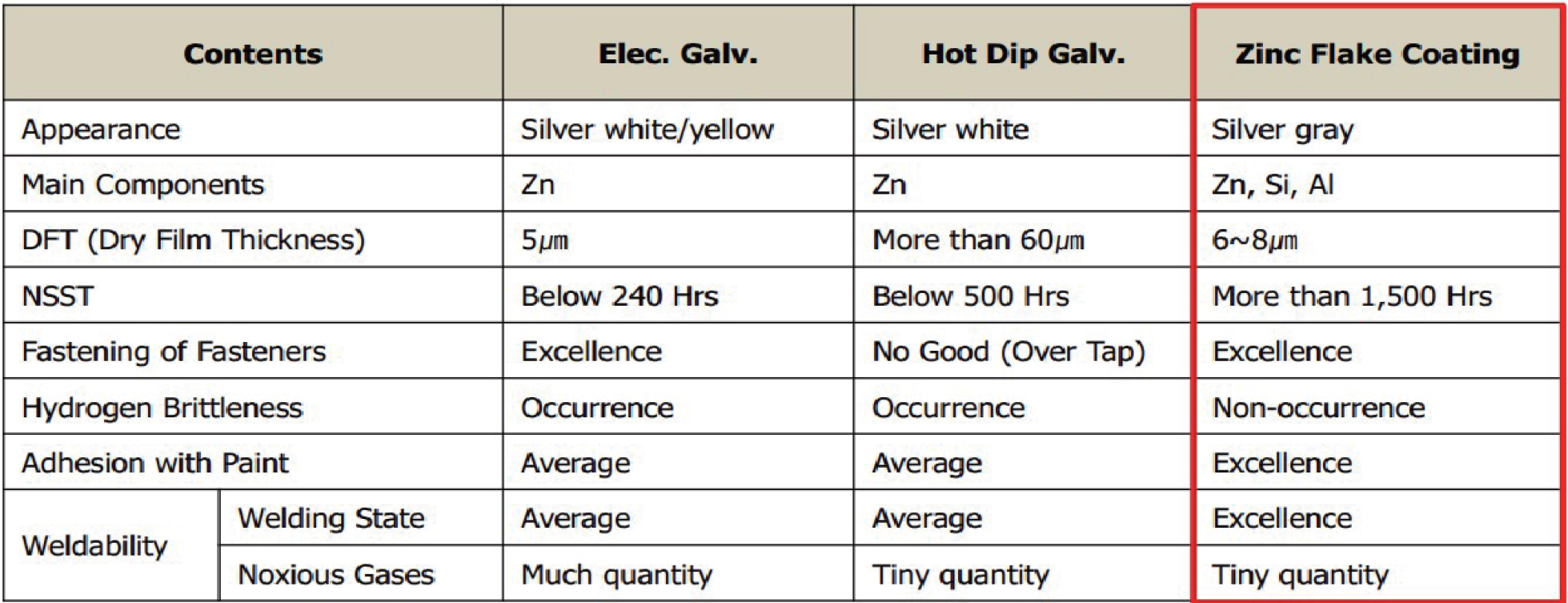

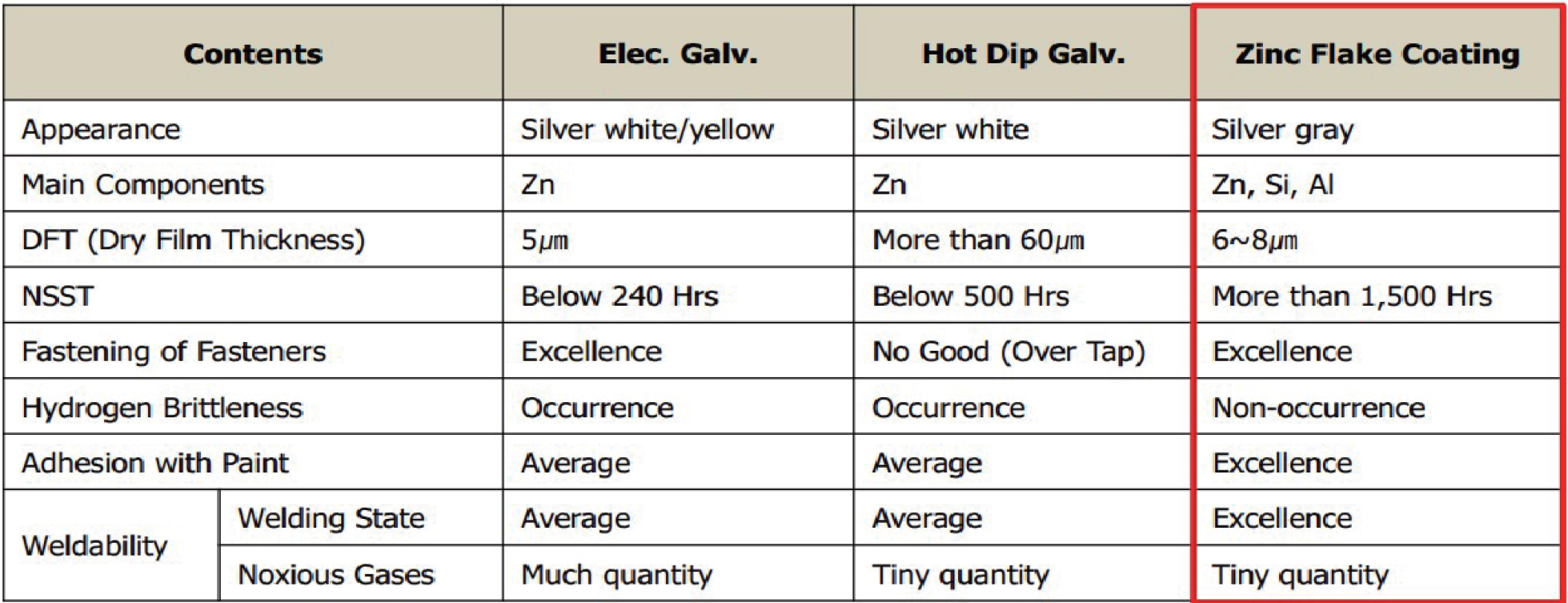

Galvanizing vs GEOCOTE specification

Electro galvanizing vs Hot dip galvanizing vs Zinc Flake Coating

Galvanizing vs GEOCOTE specification

Electro galvanizing vs Hot dip galvanizing vs Zinc Flake Coating

Galvanizing vs GEOCOTE salt spray

Test per steel grade after applying GEOCOTE

Galvanizing vs GEOCOTE salt spray

Test per steel grade after applying GEOCOTE

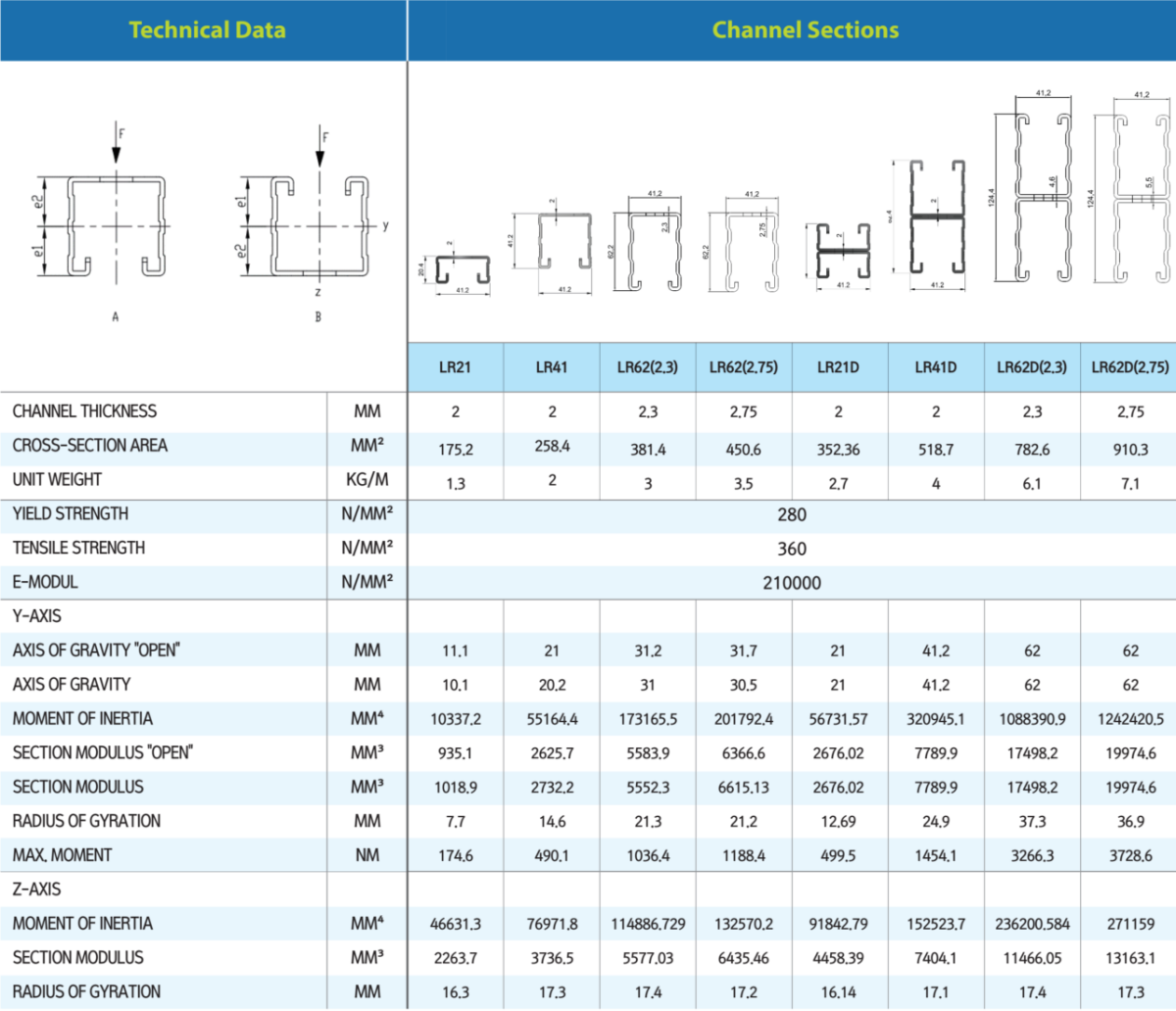

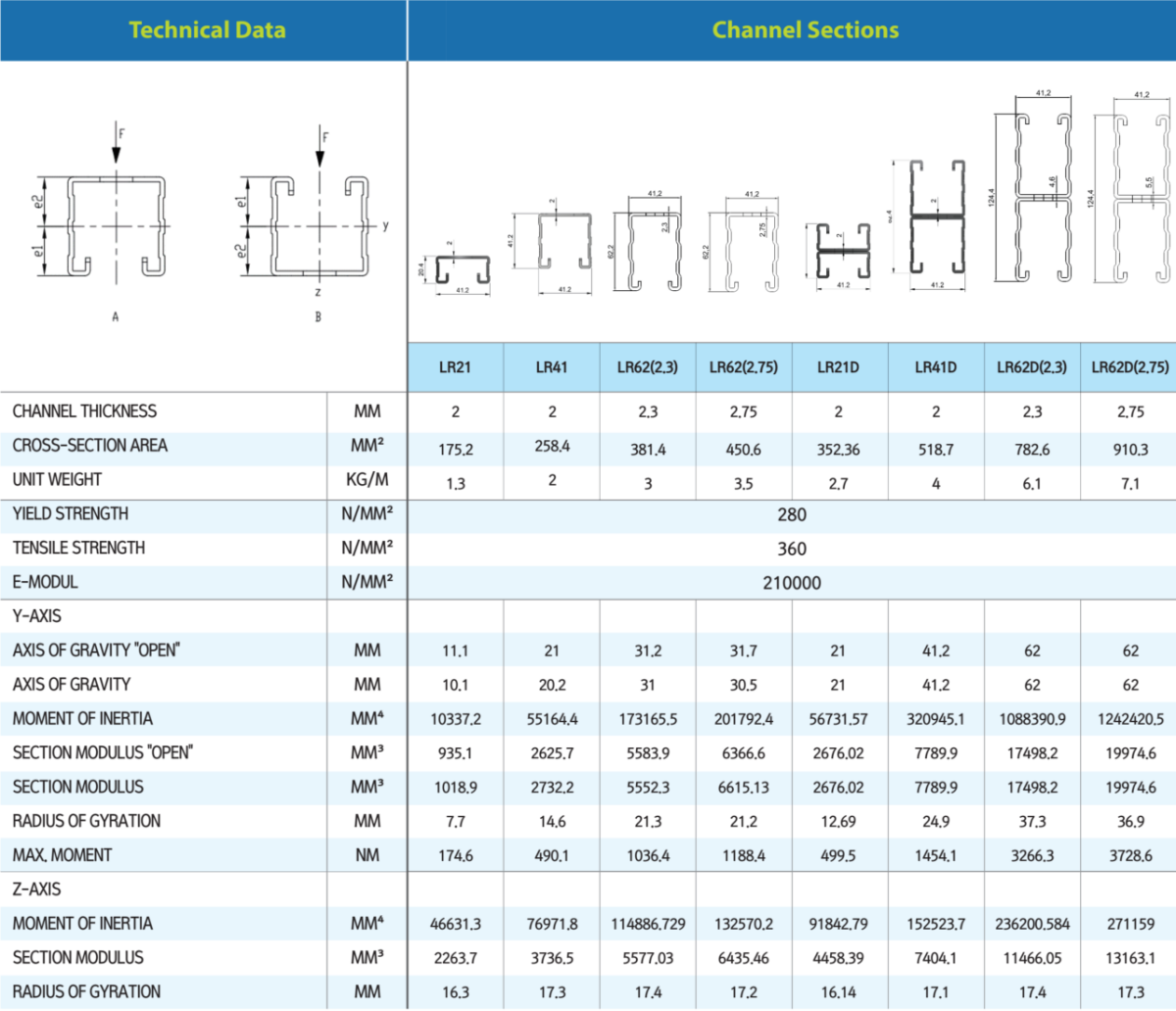

TECHNICAL DATA

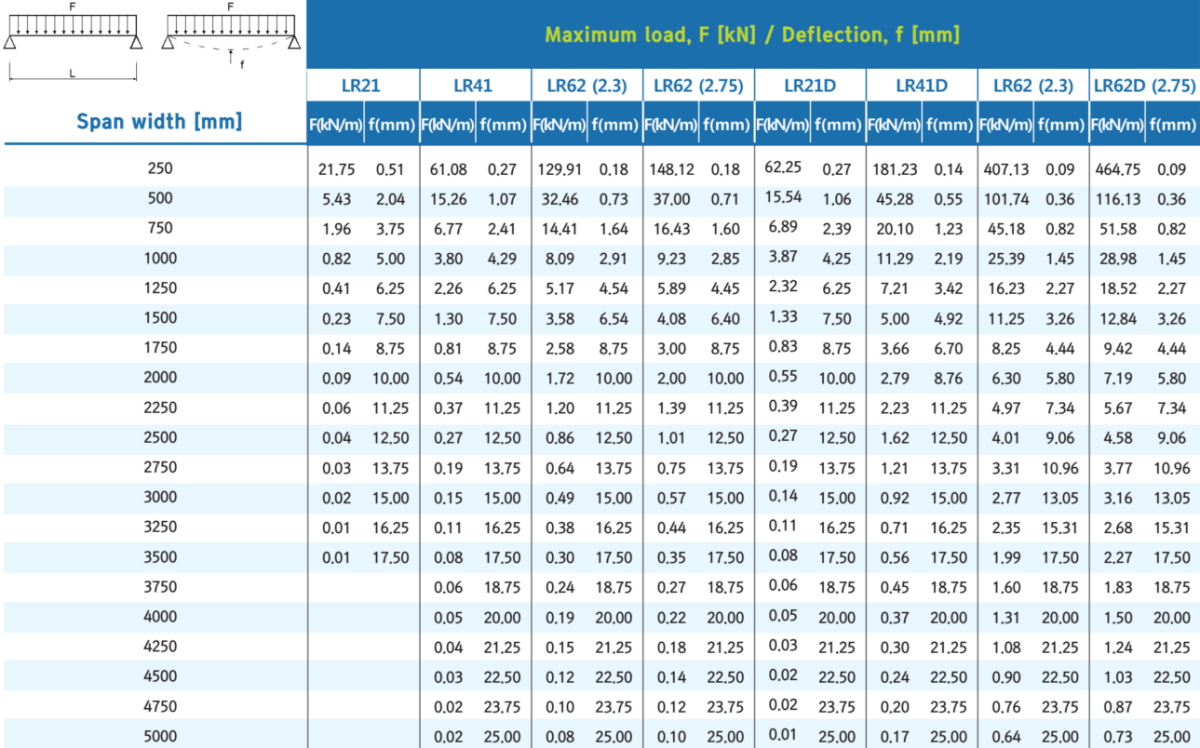

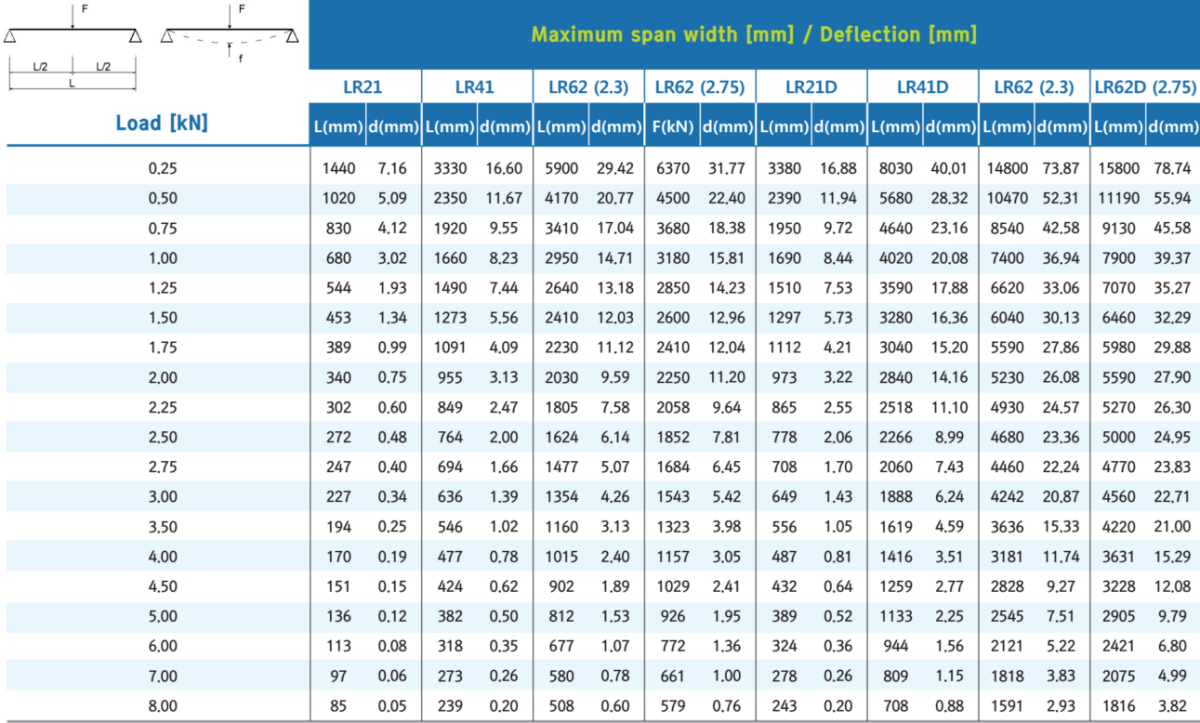

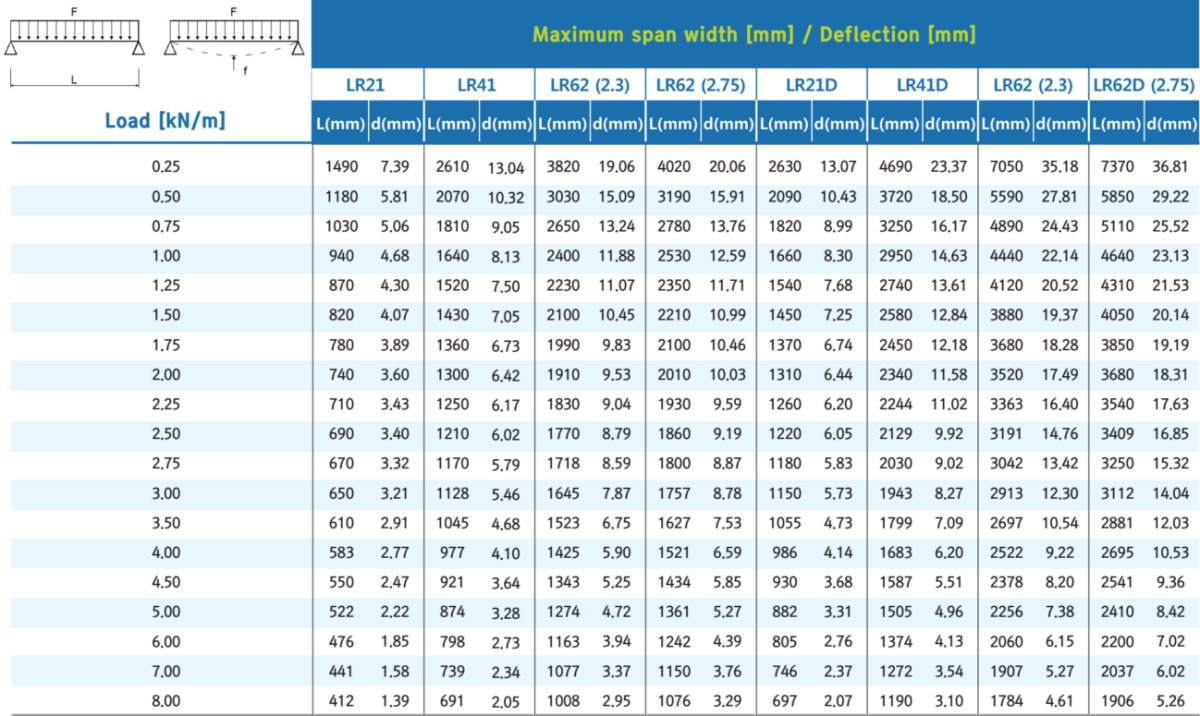

Channel Performance

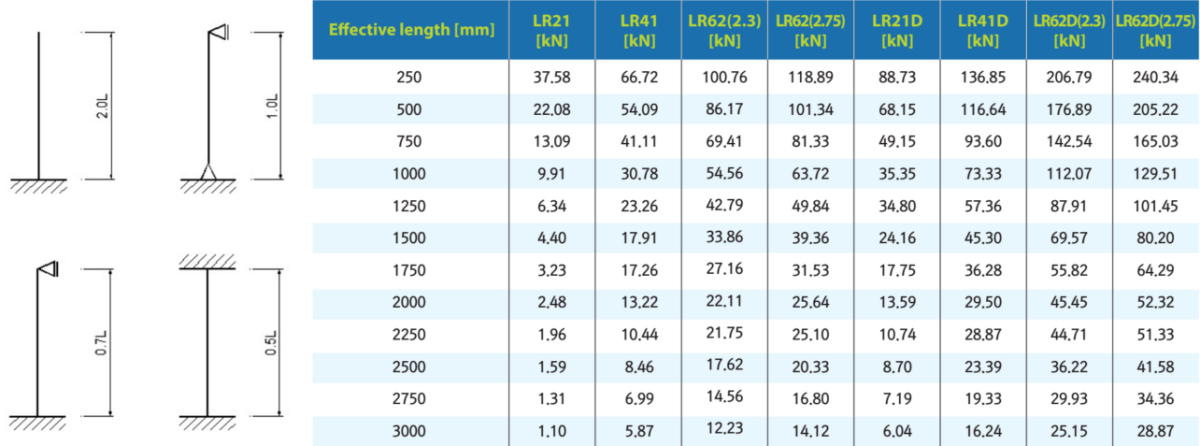

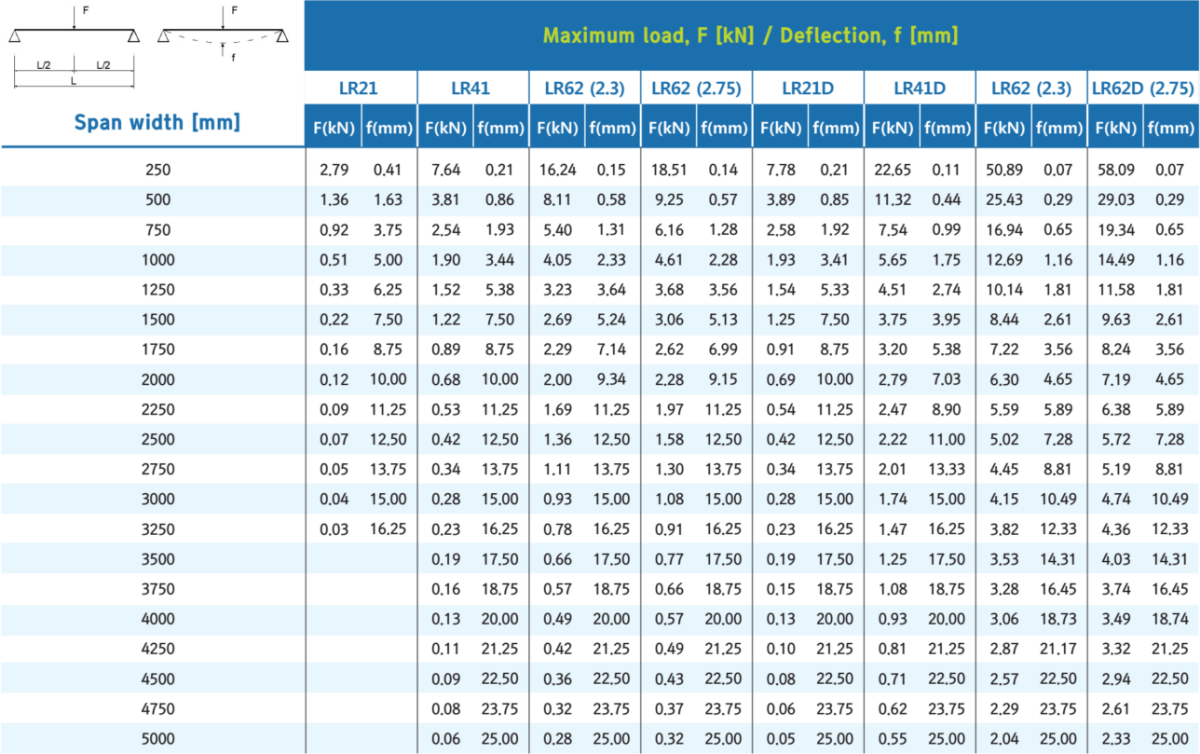

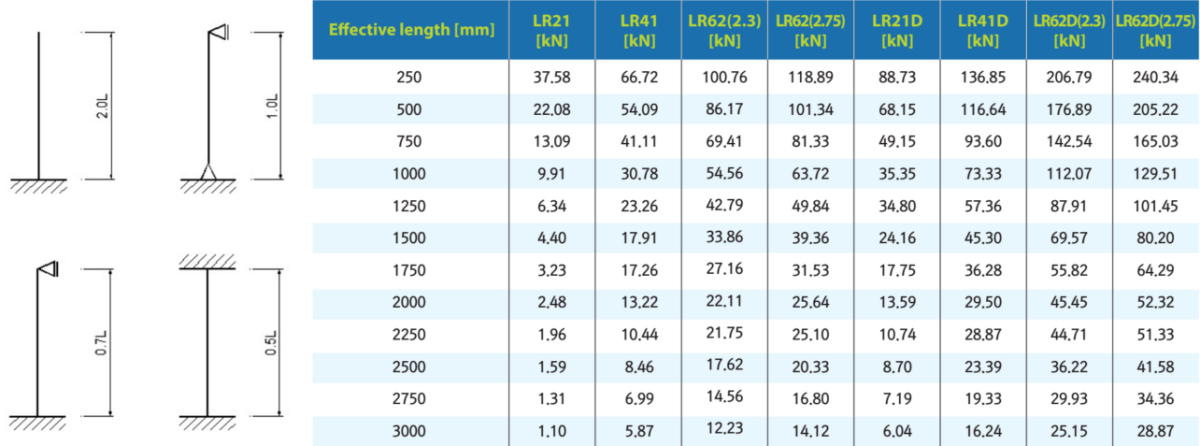

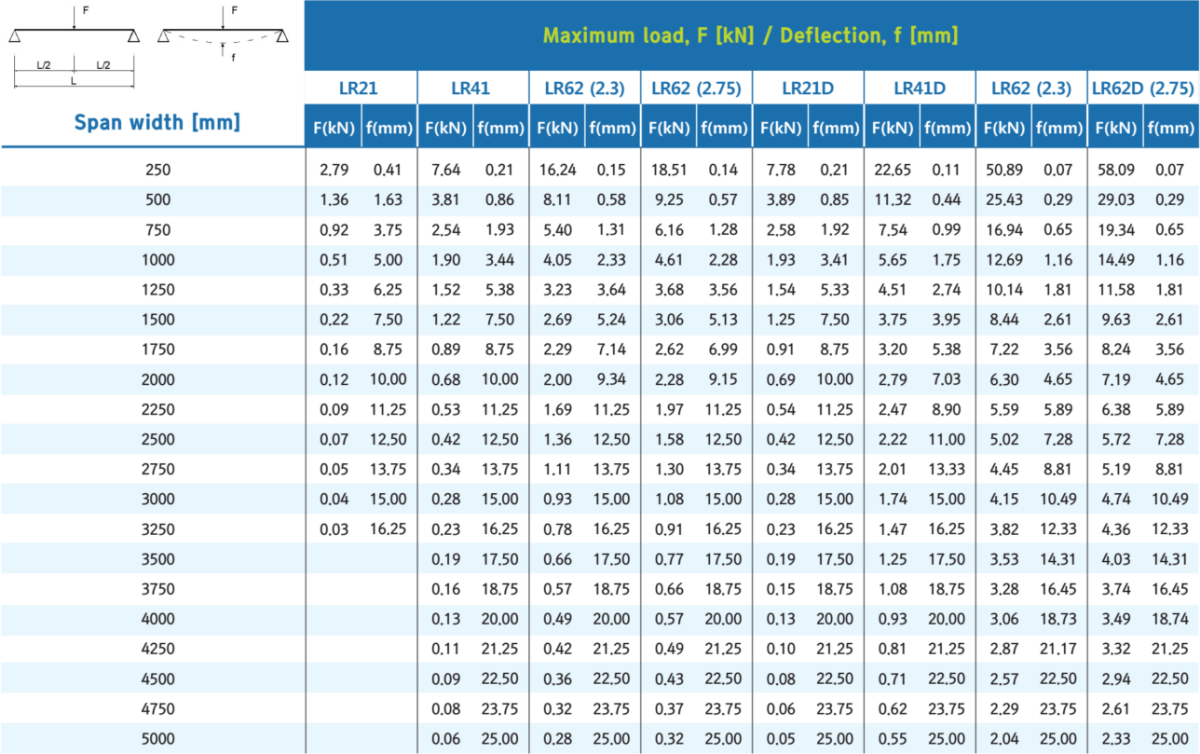

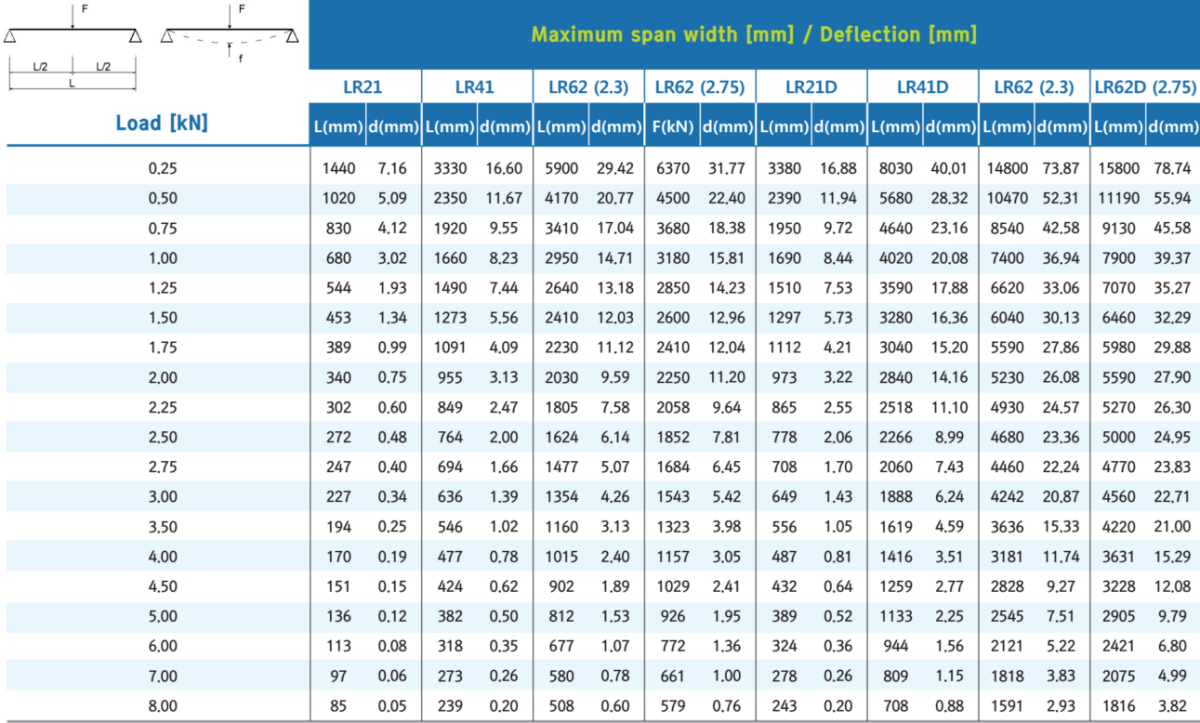

Channel Load Table

Channel Load Table

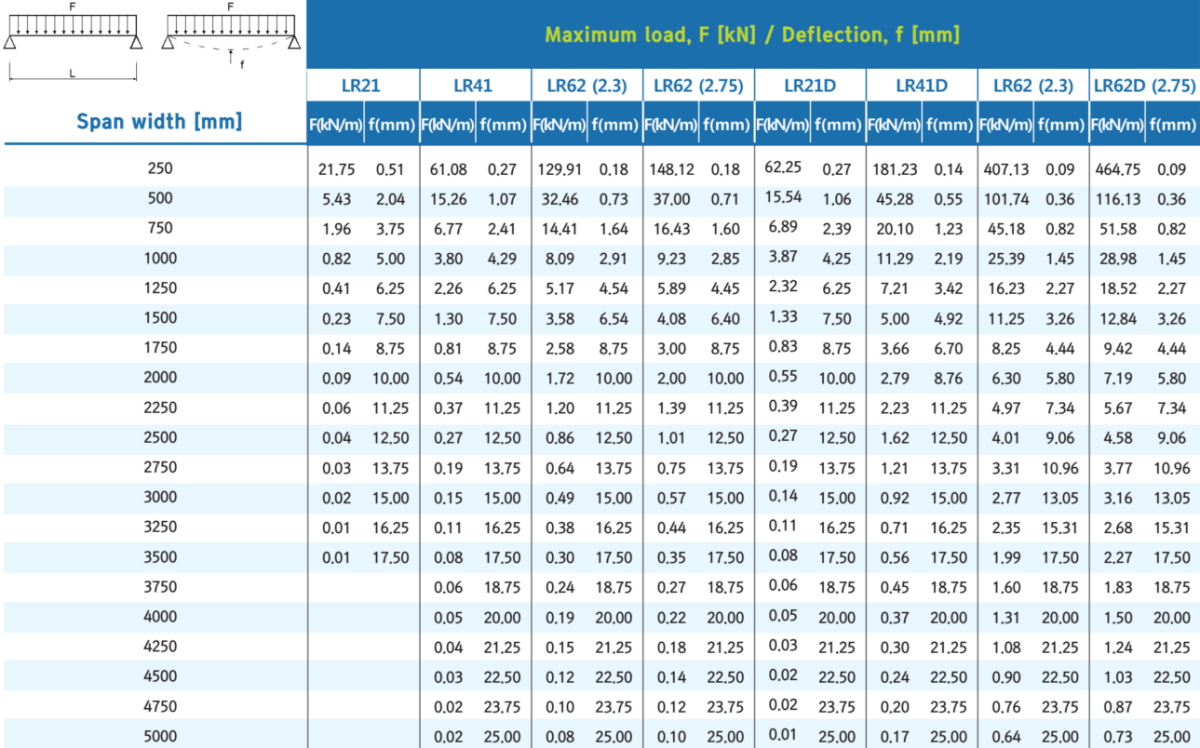

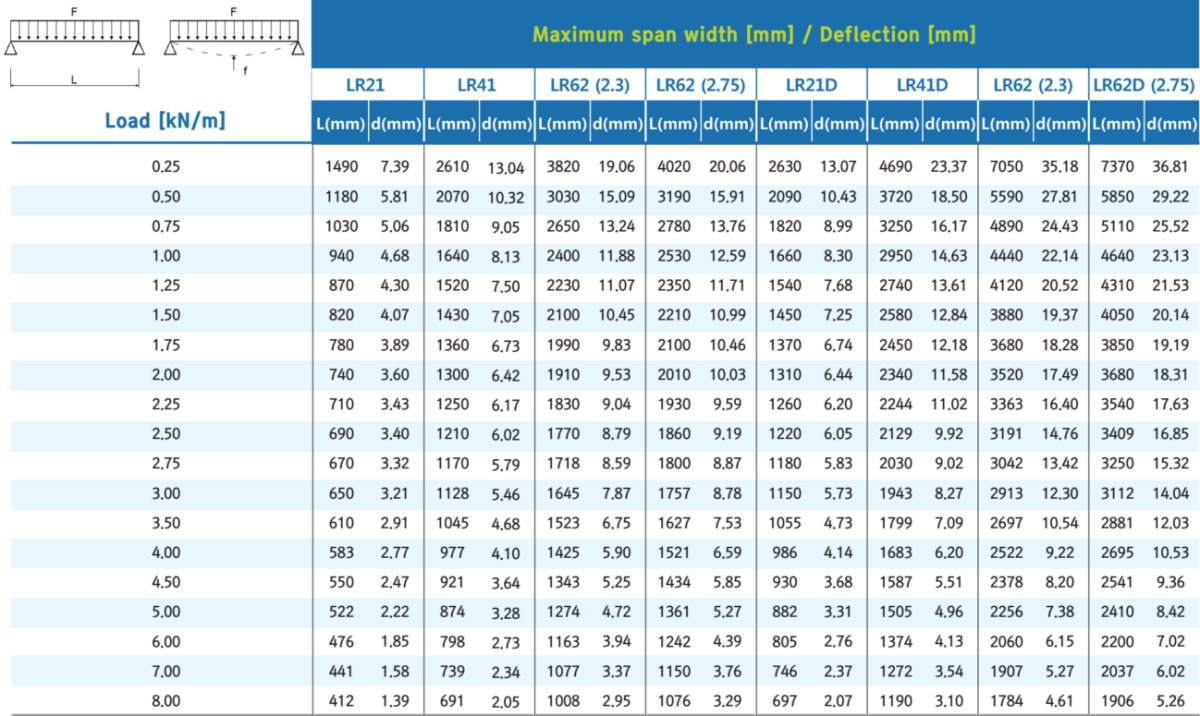

Channel Load Table

Channel Load Table

Channel Load Table

Channel Load Table

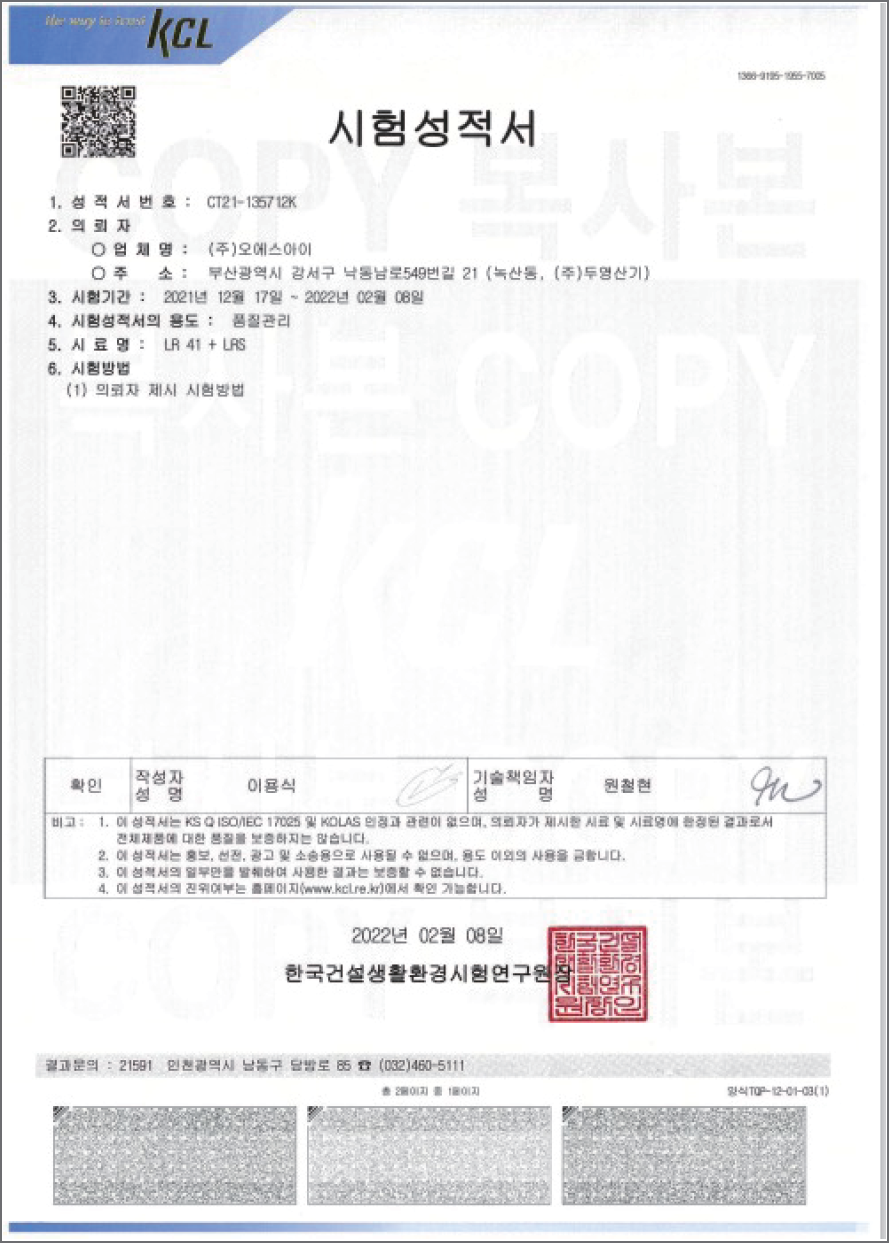

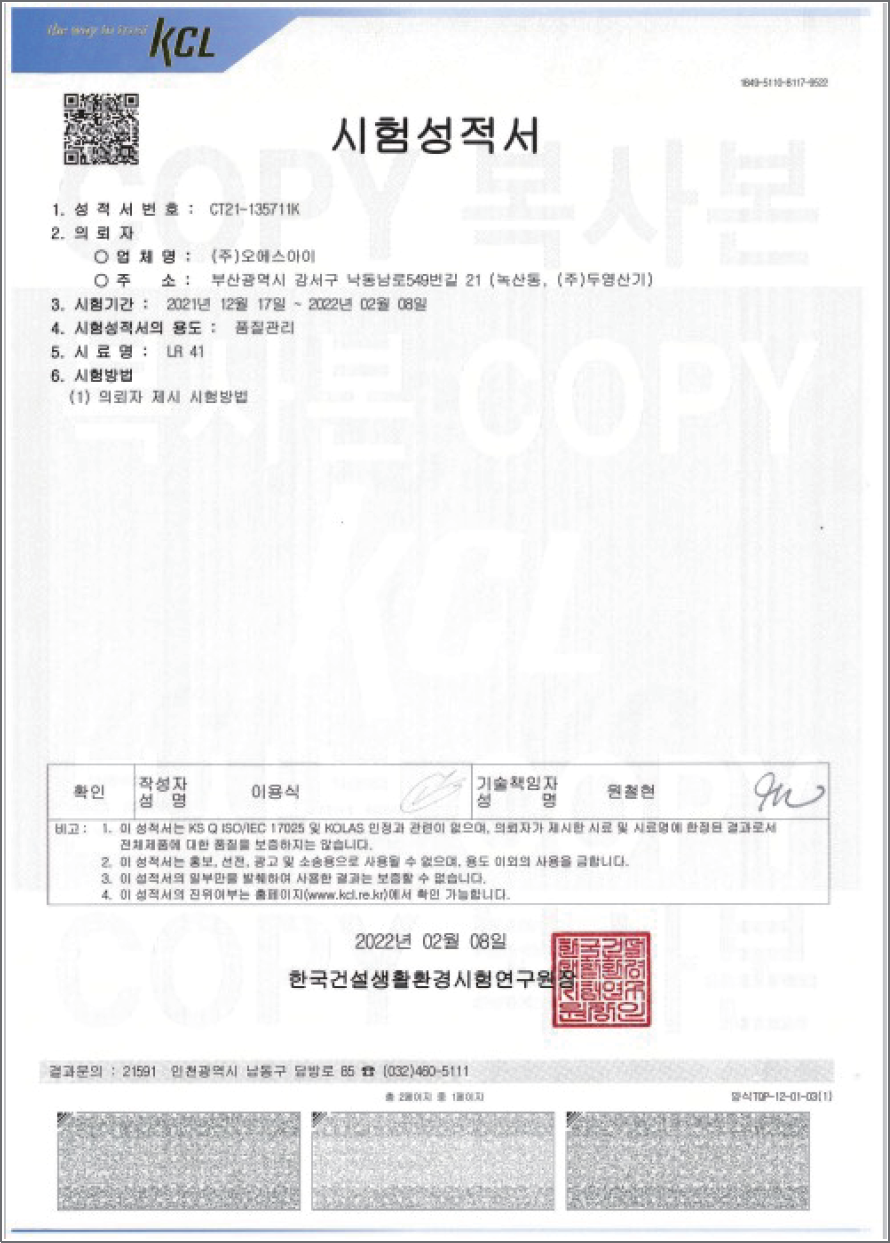

Korea Conformity Laboratories Test Report

Korea Conformity Laboratories Test Report

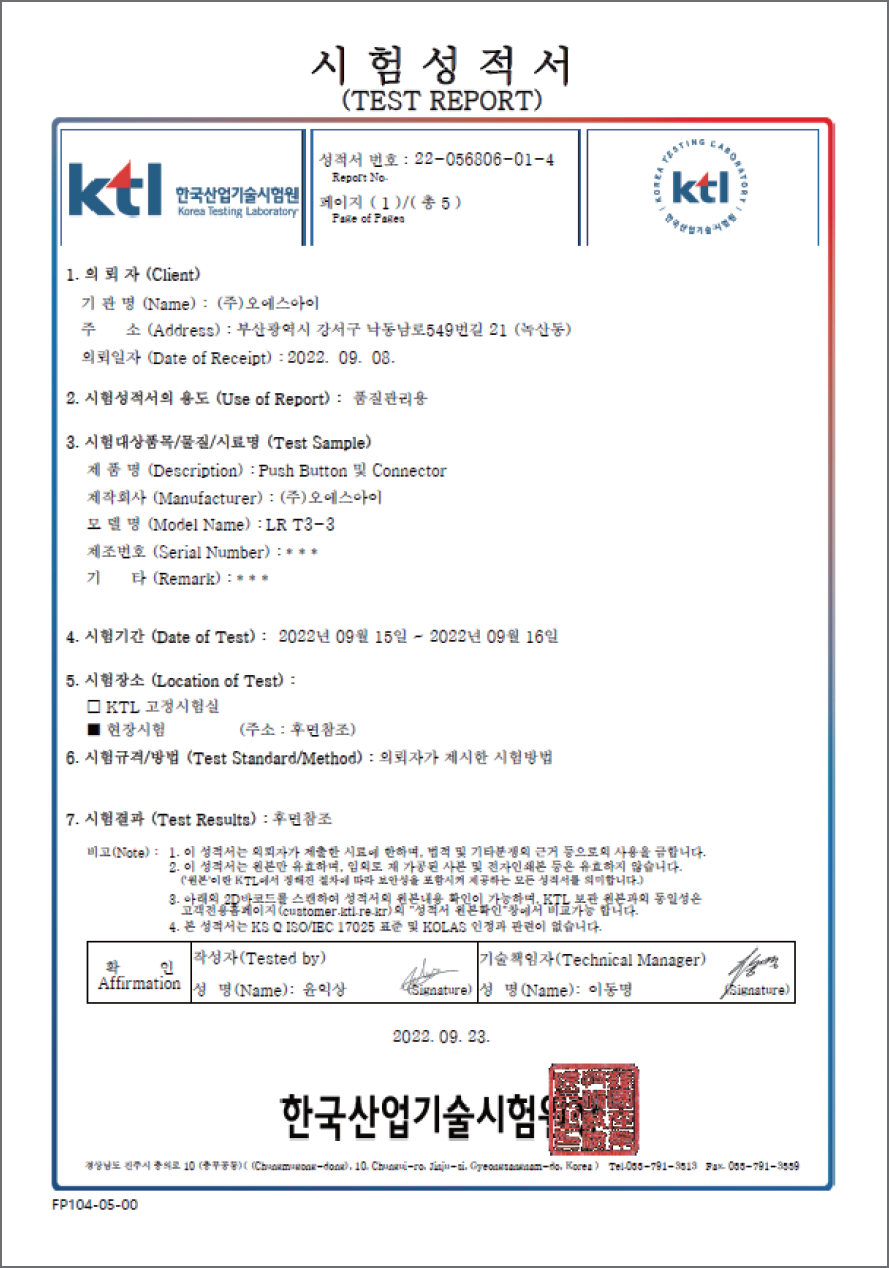

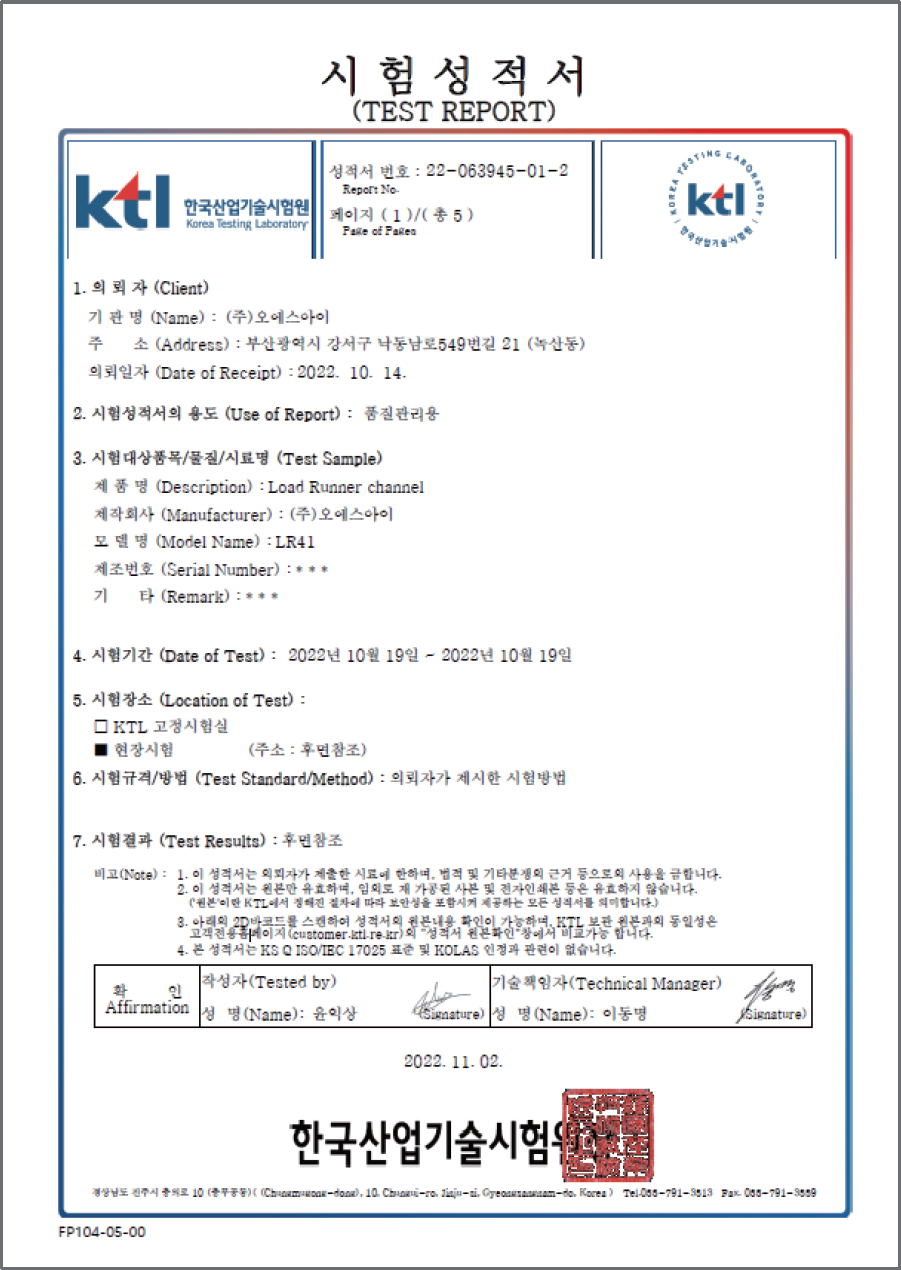

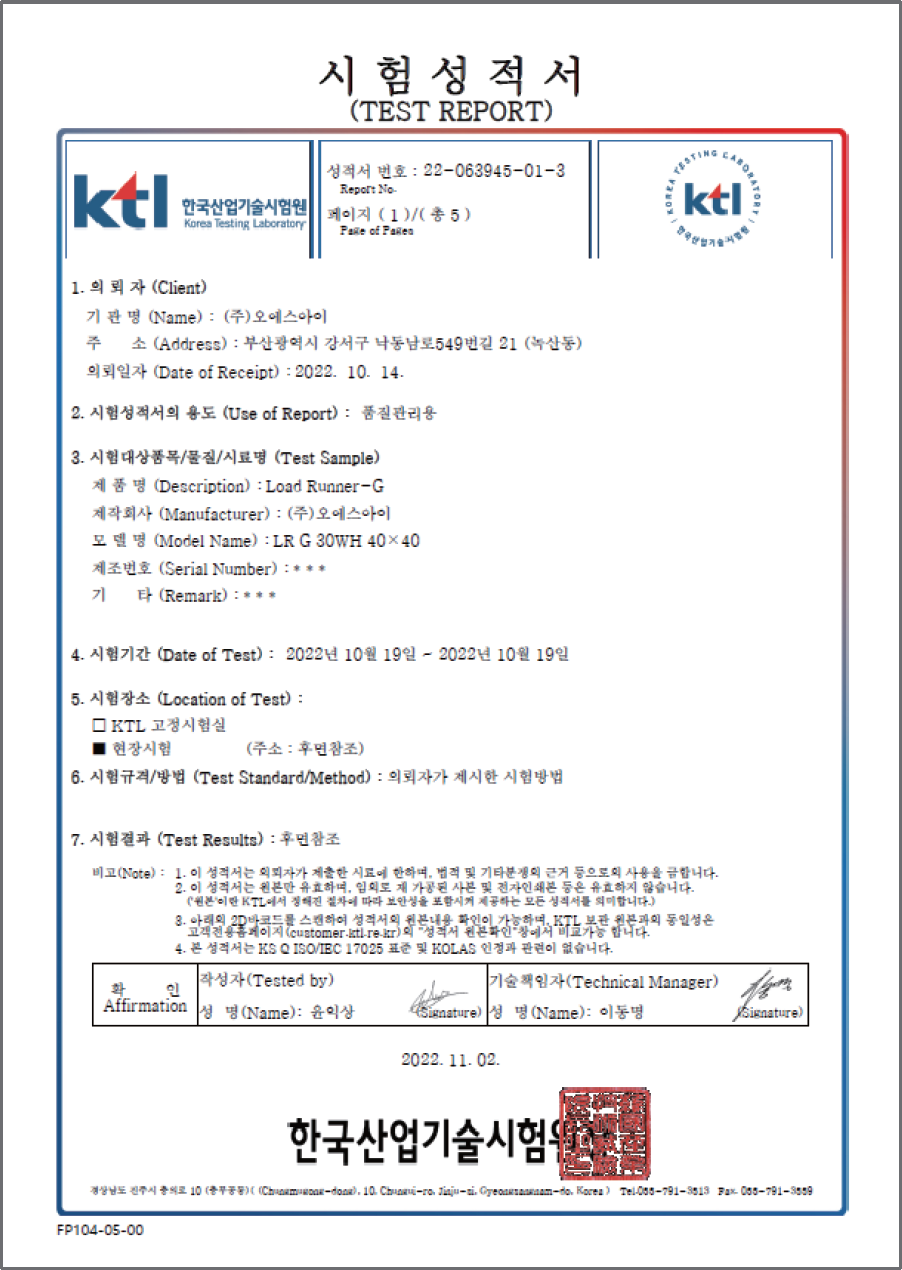

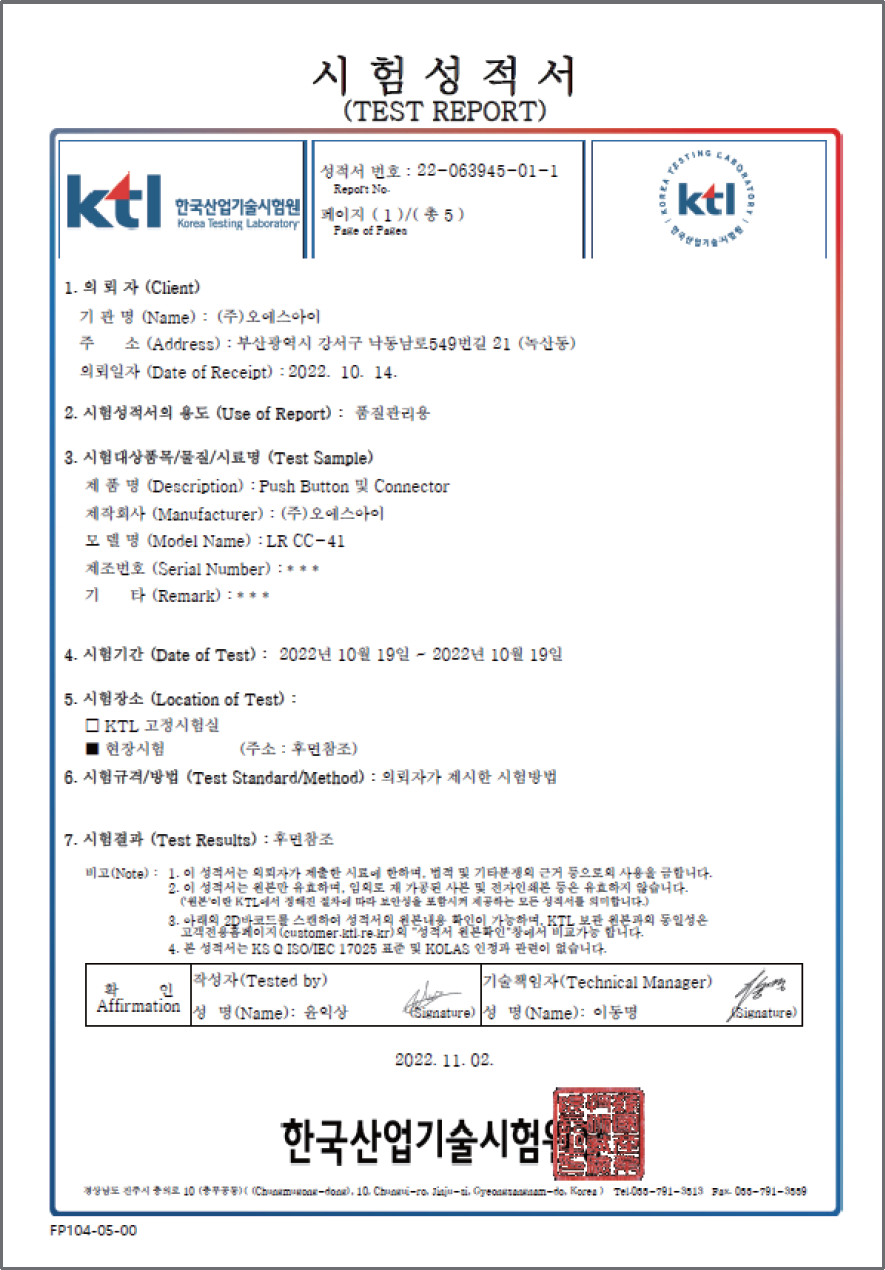

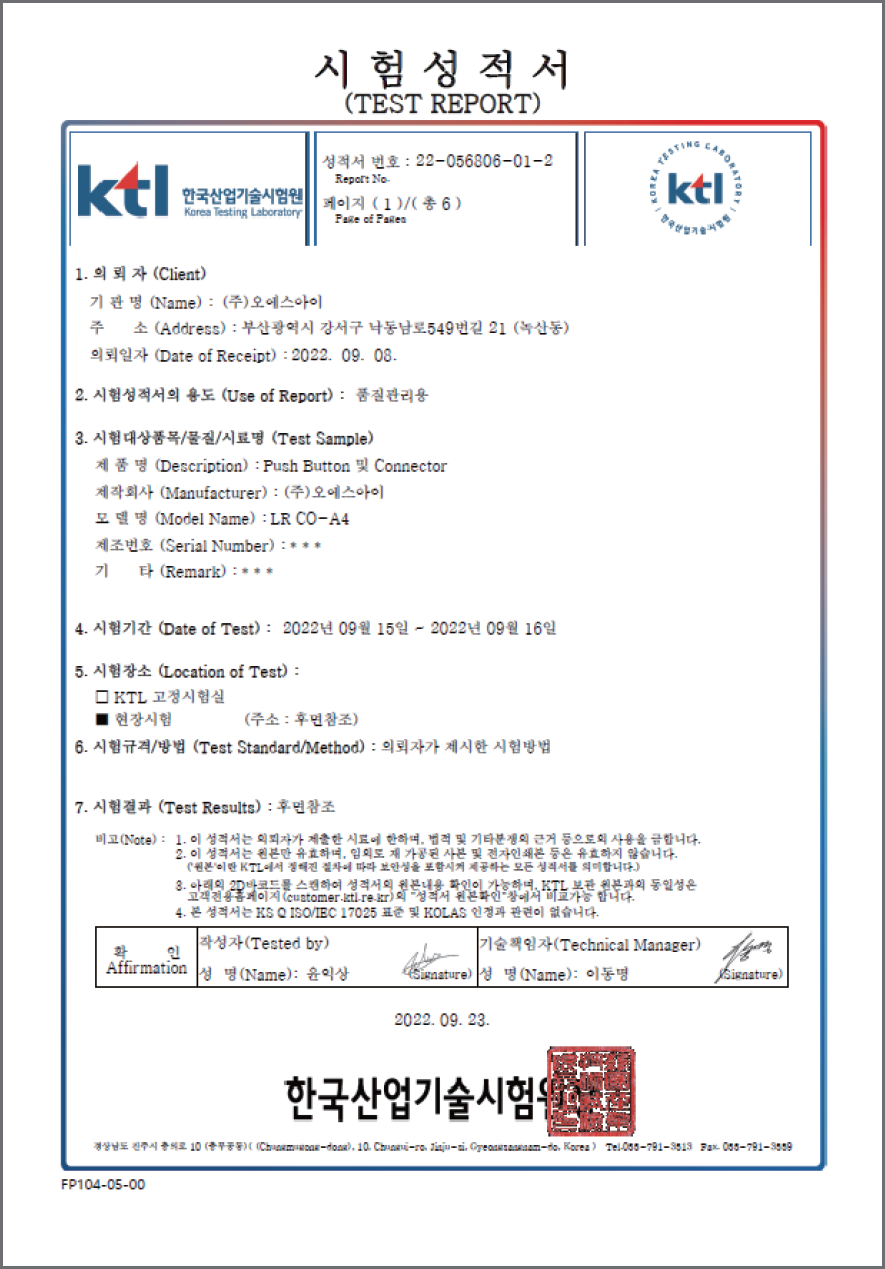

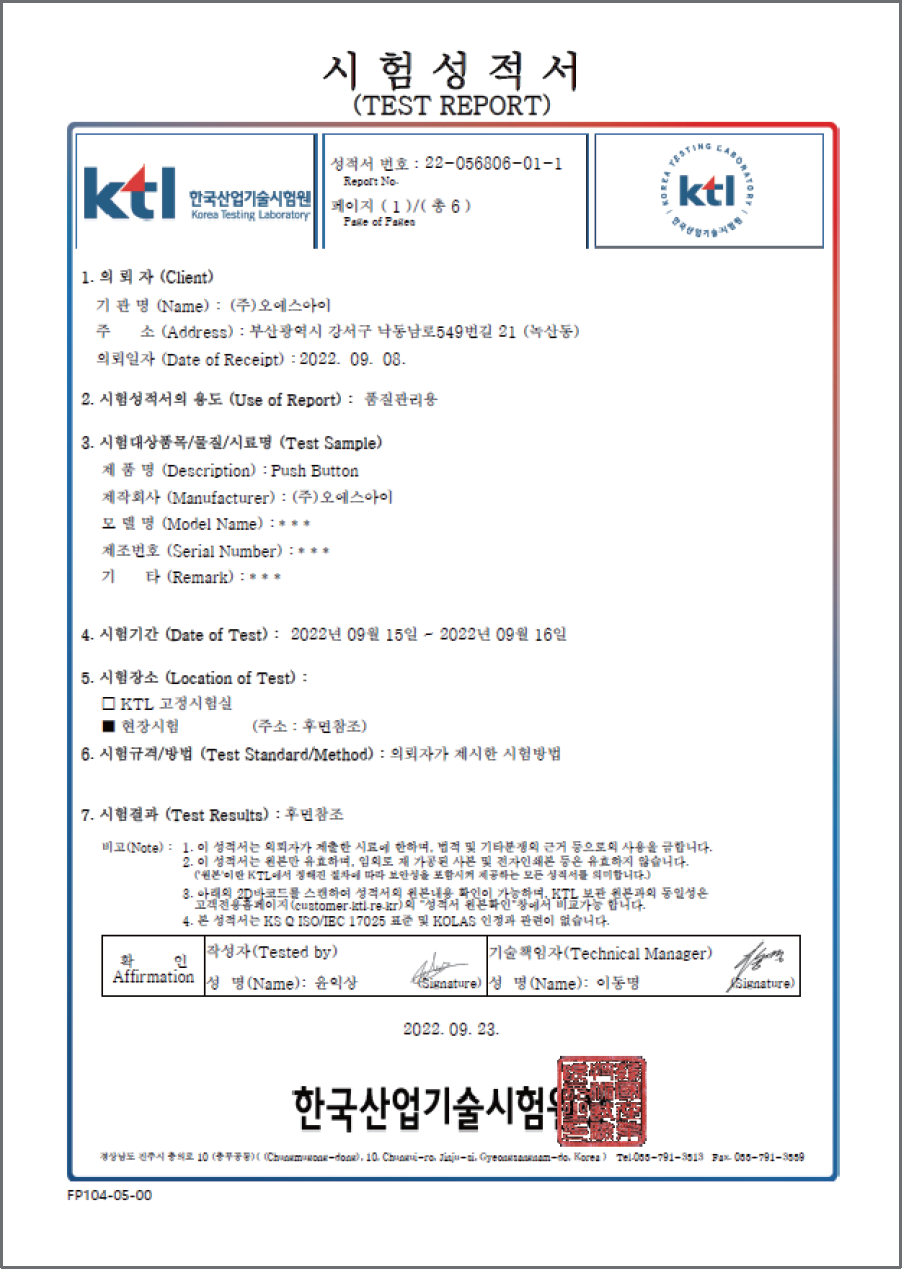

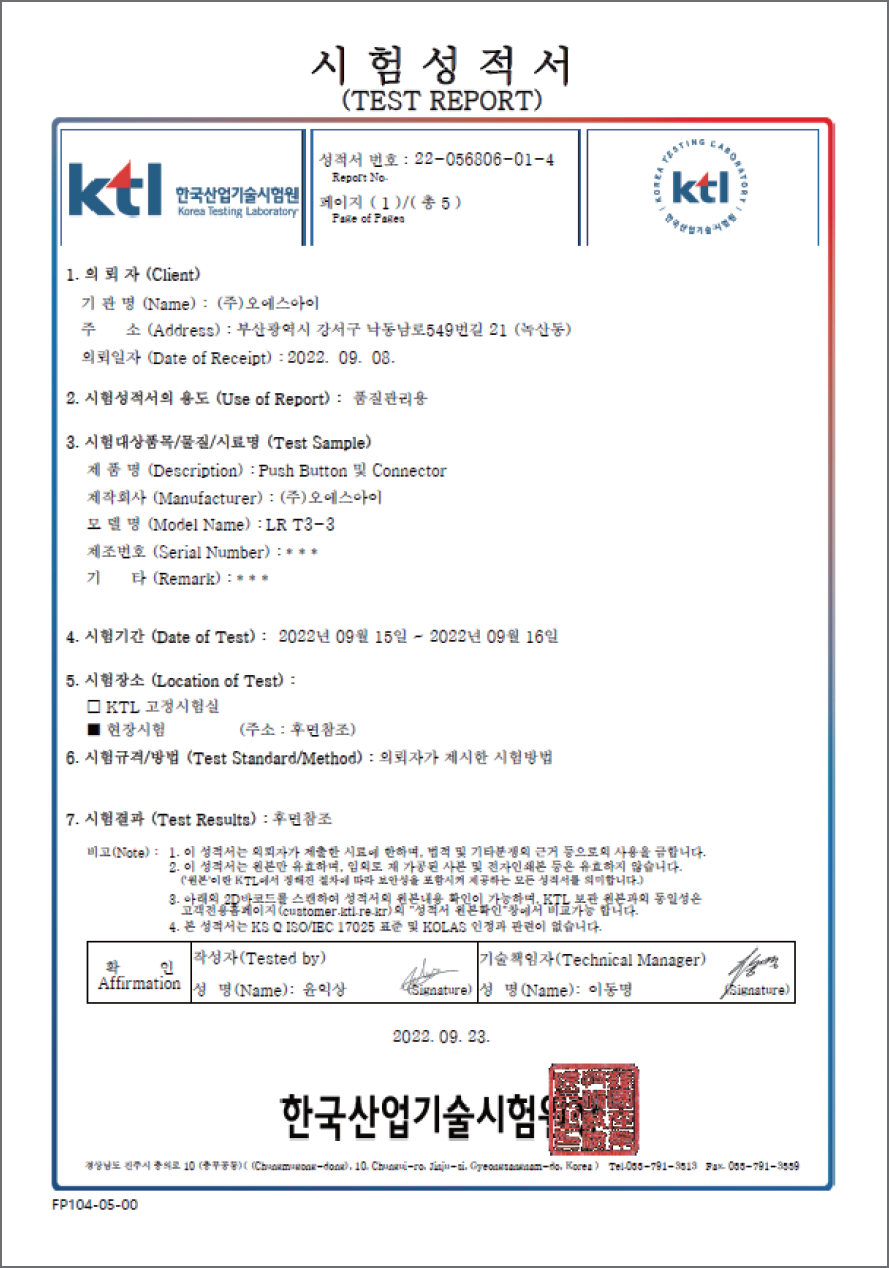

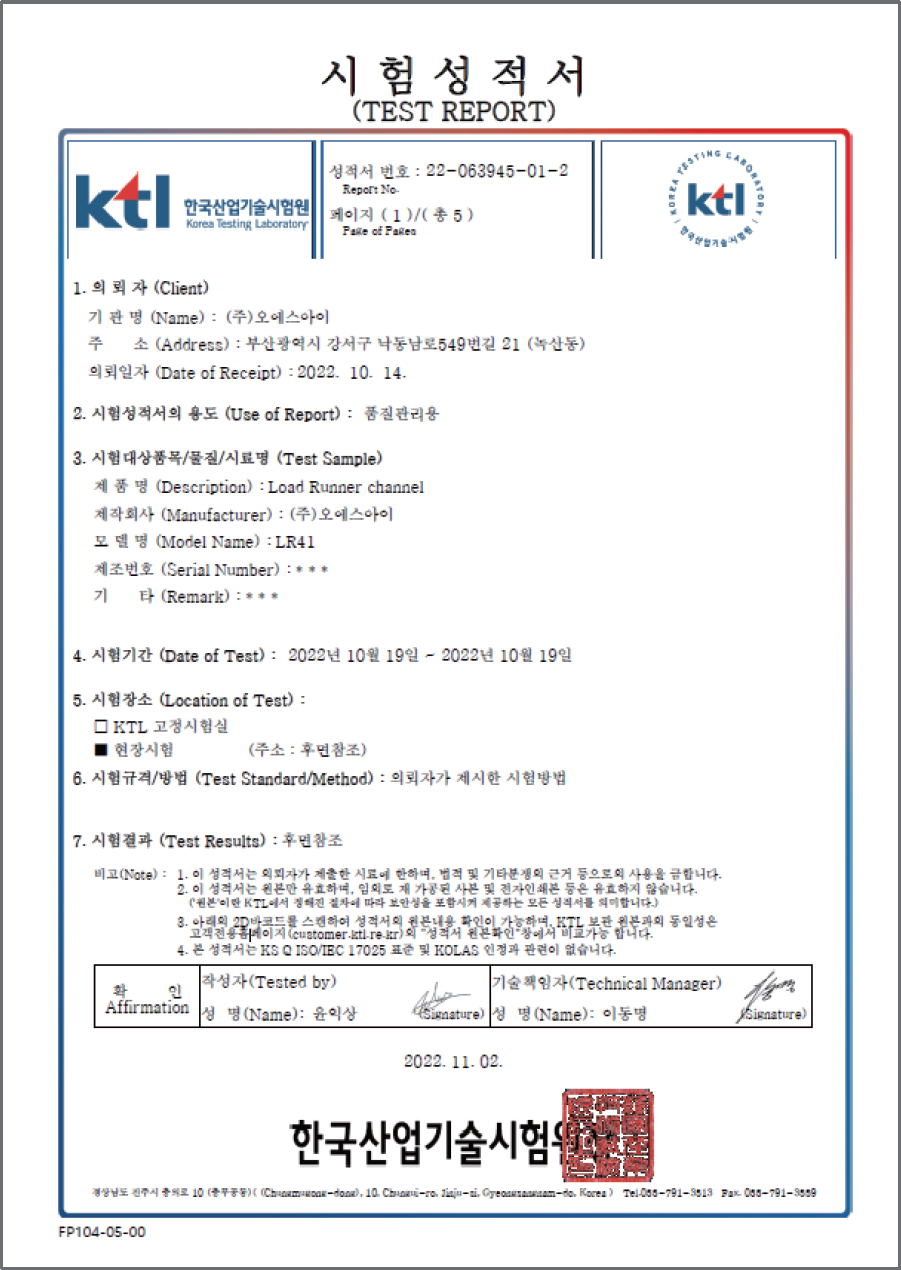

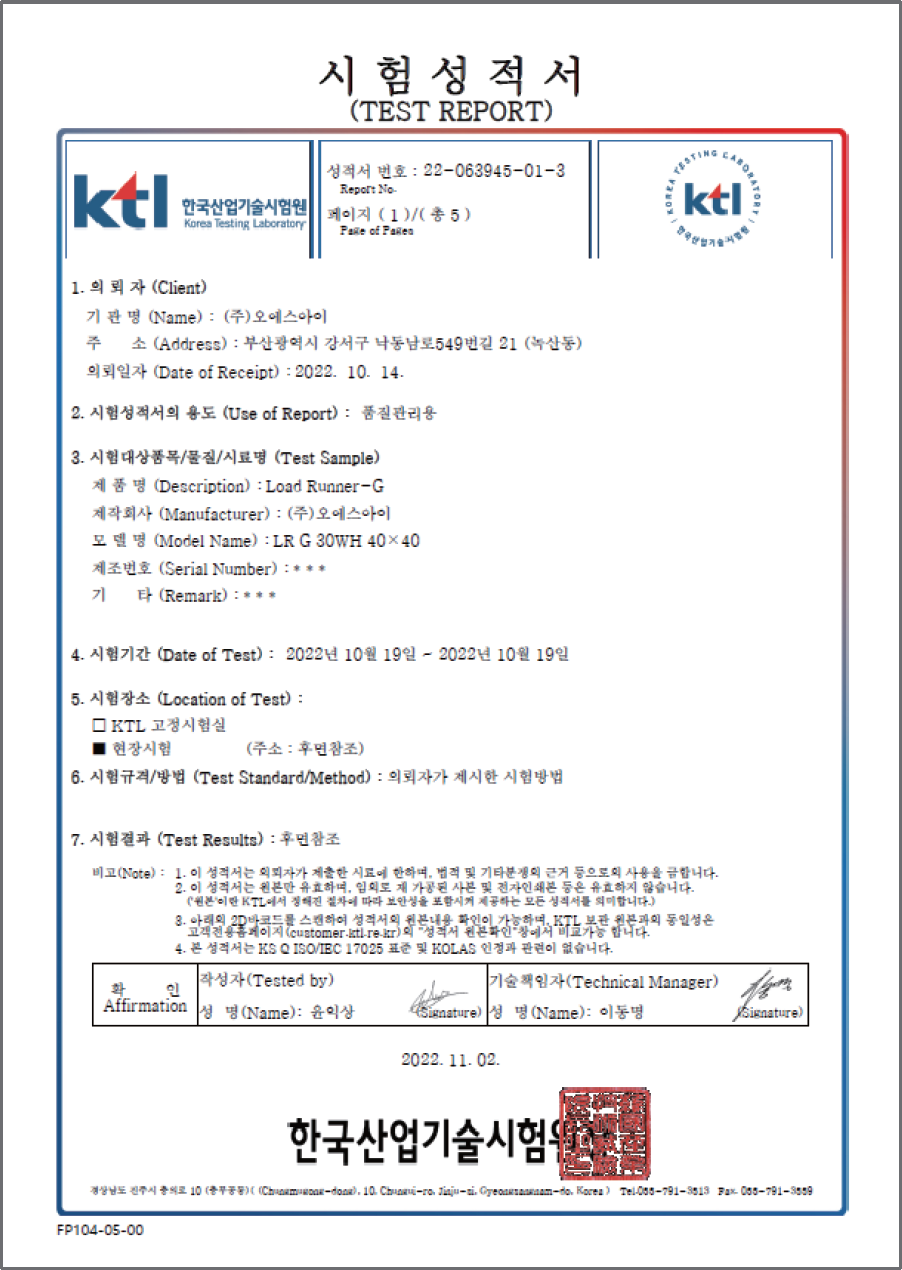

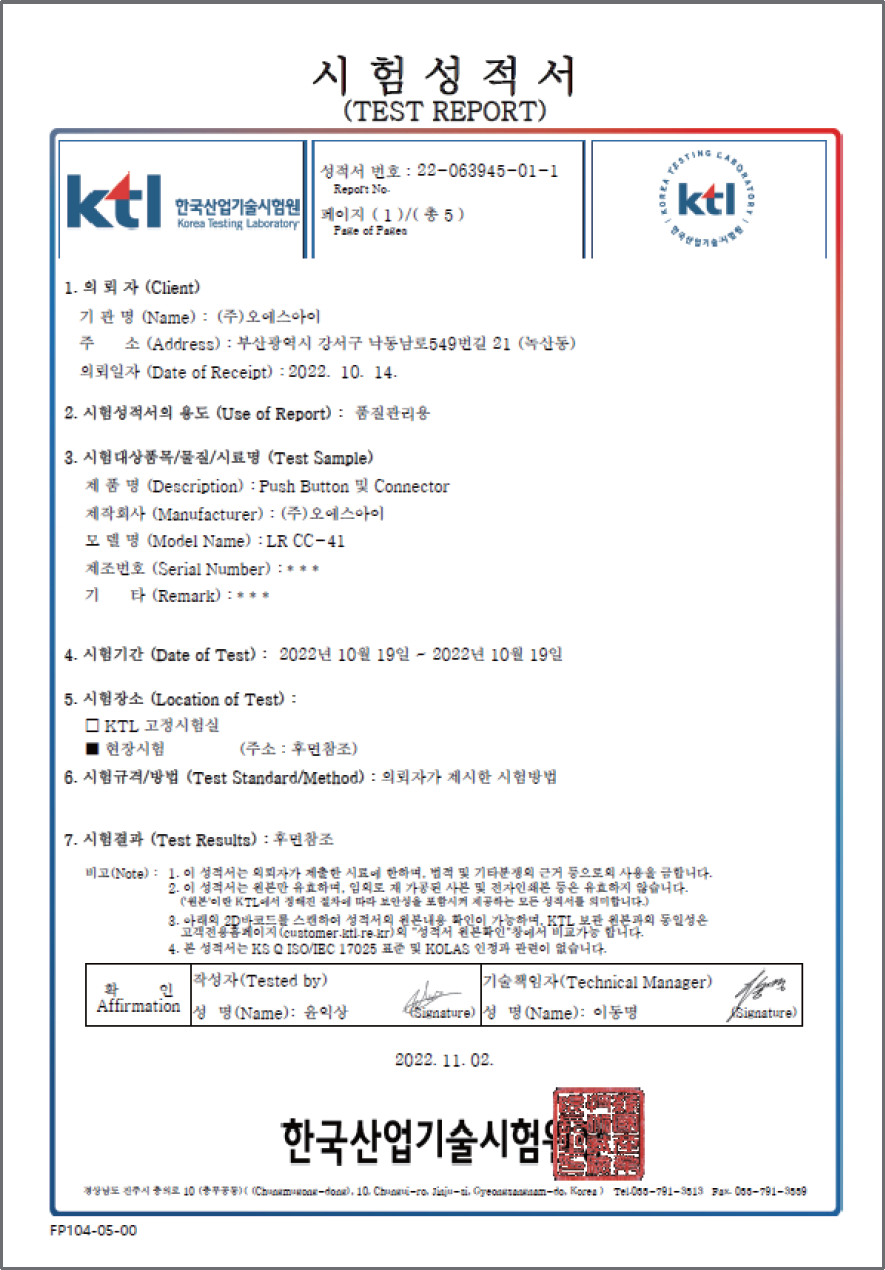

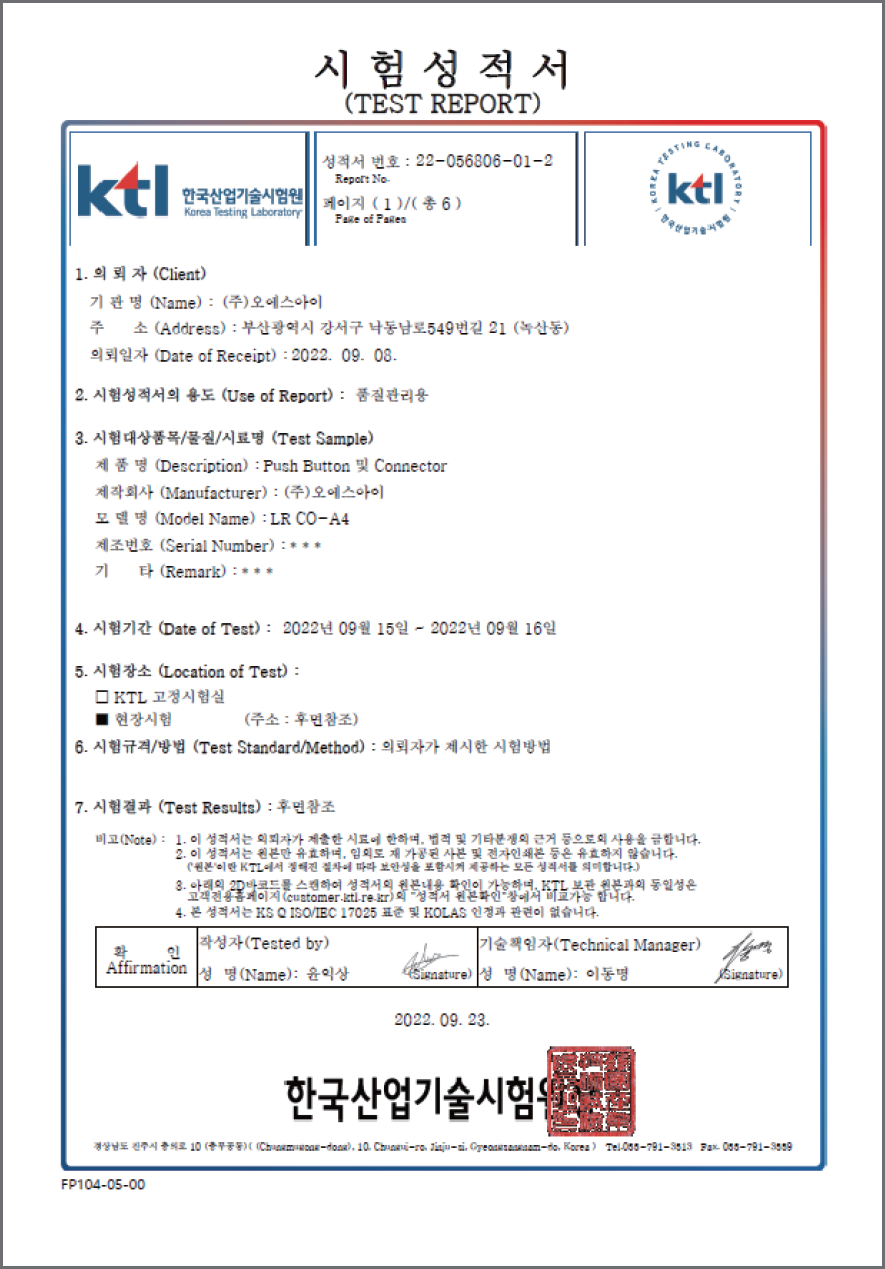

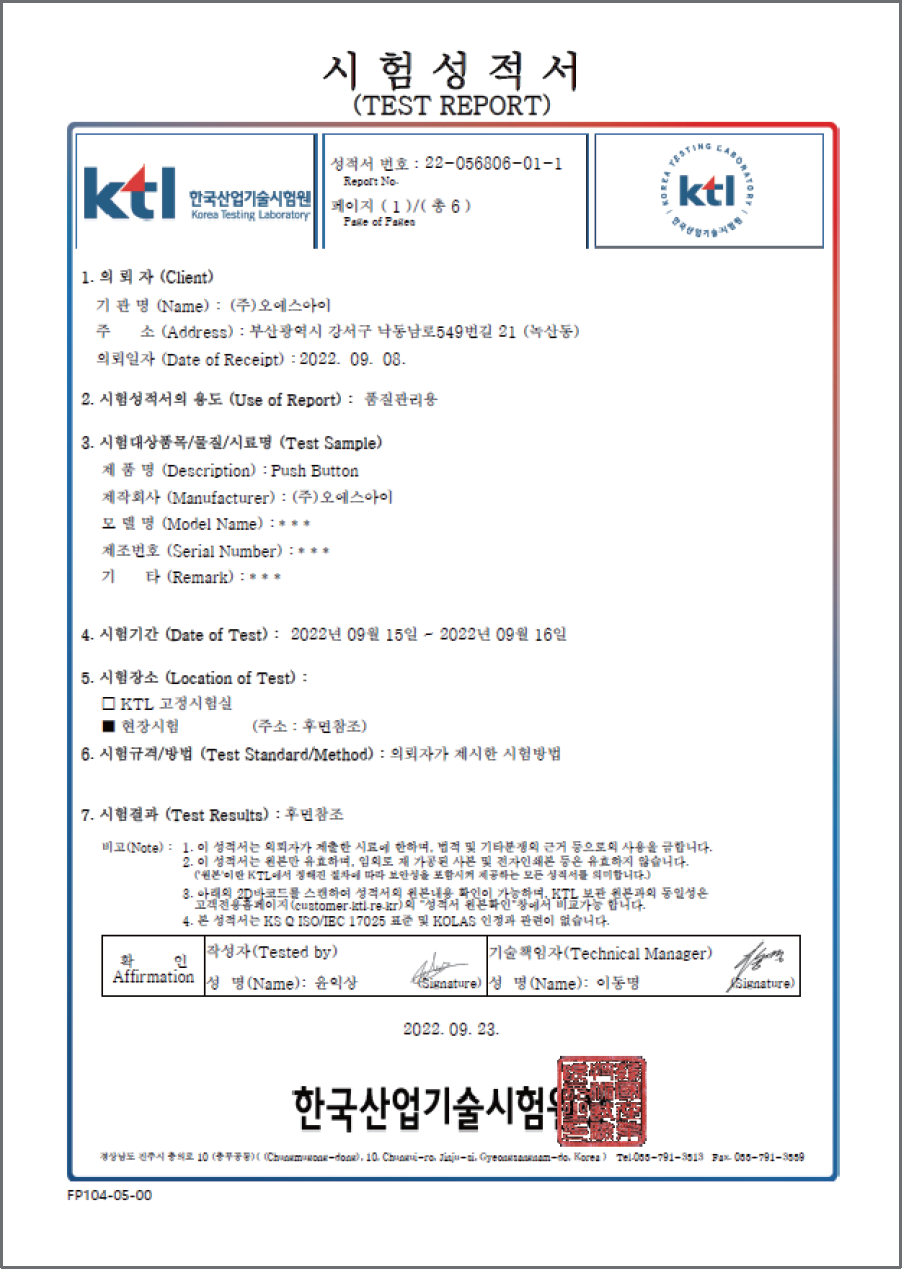

KTL(Korea Testing Laboratory) Test Report

KTL(Korea Testing Laboratory) Test Report

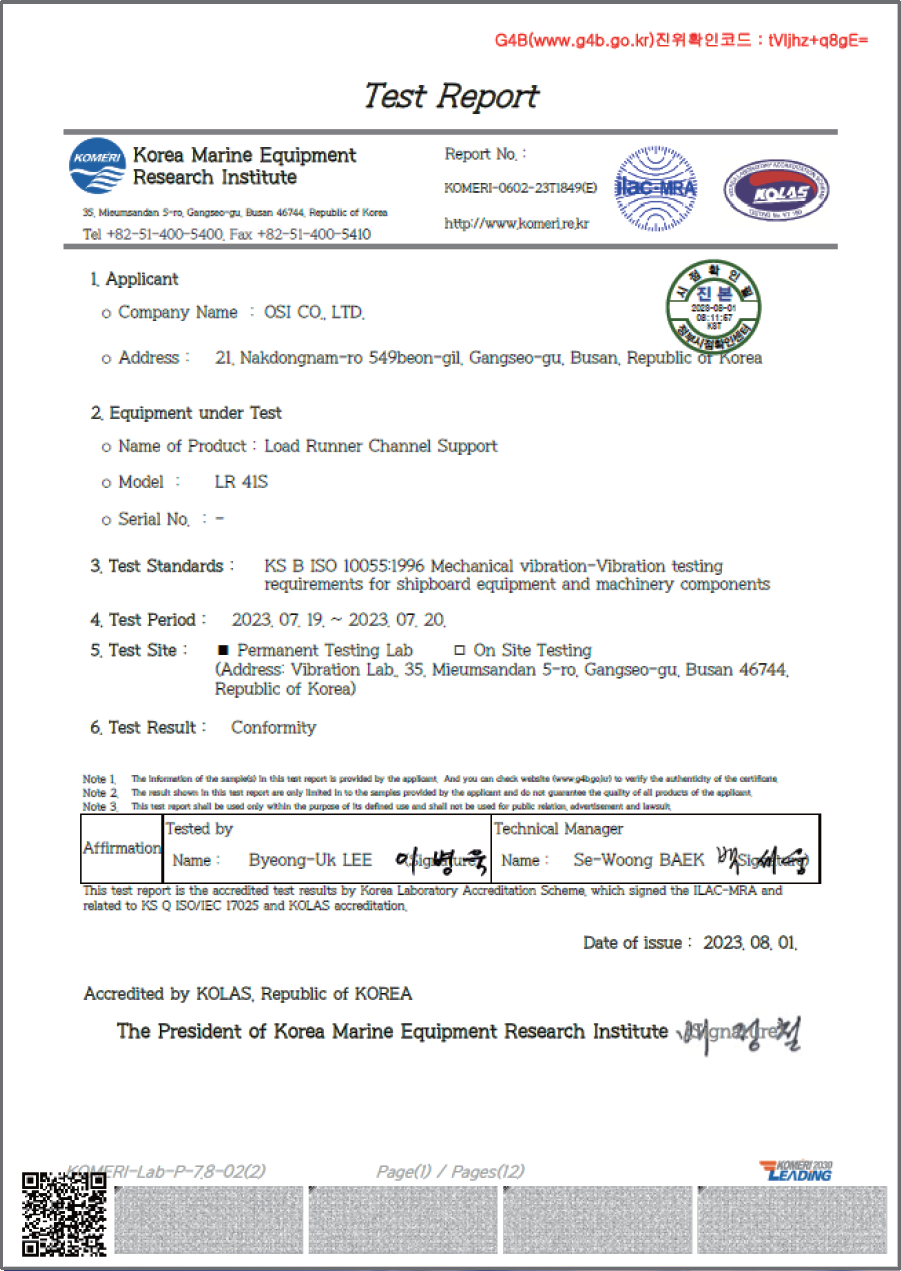

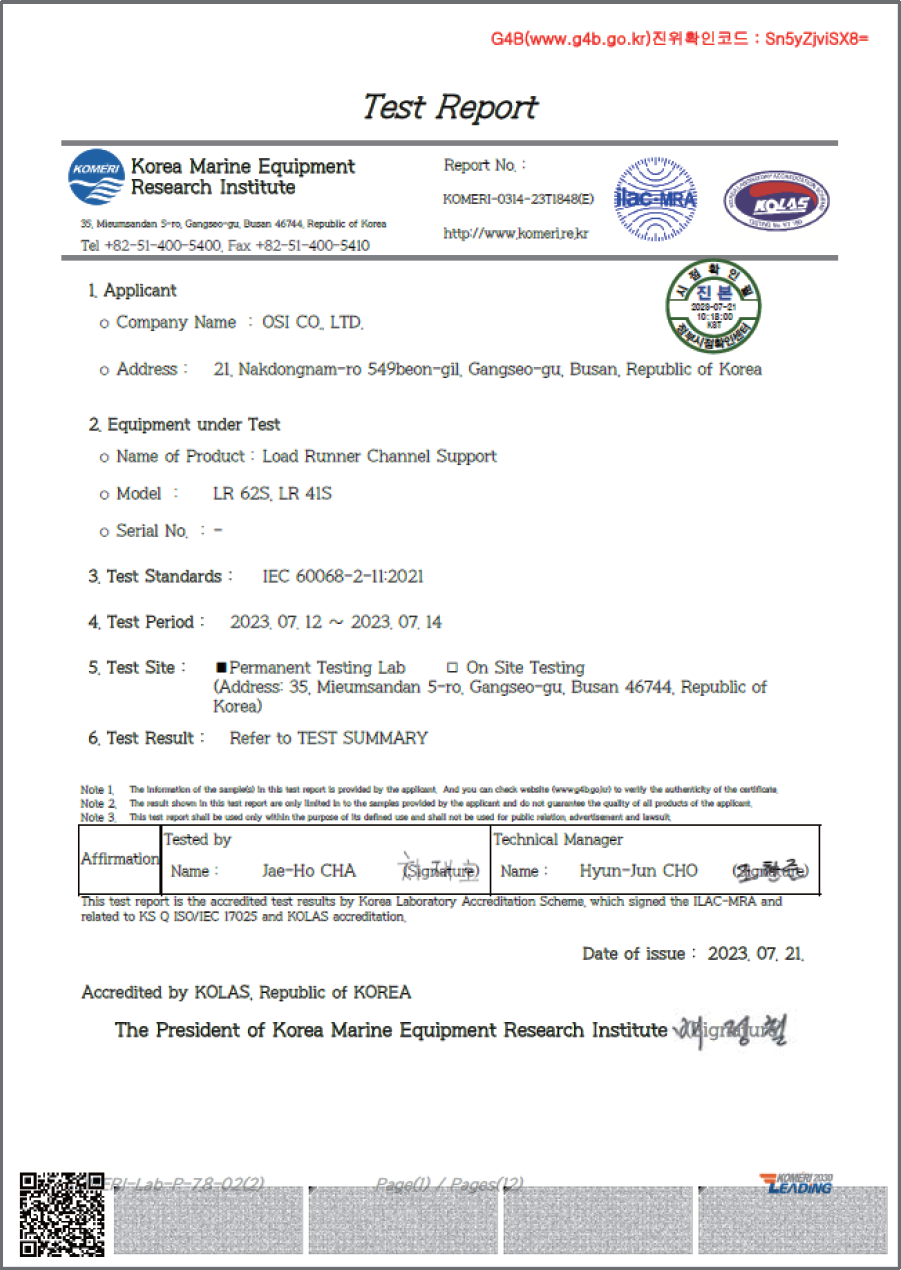

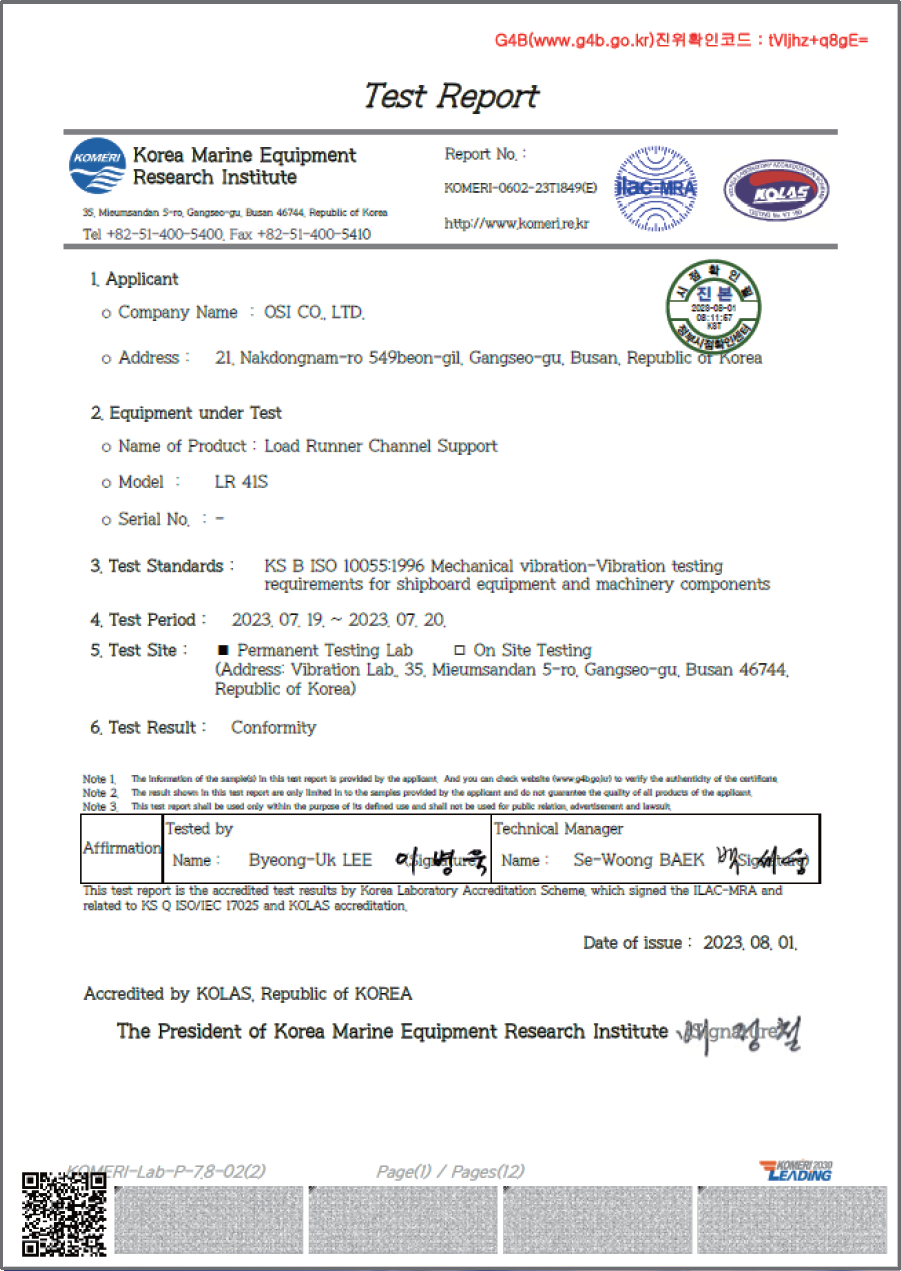

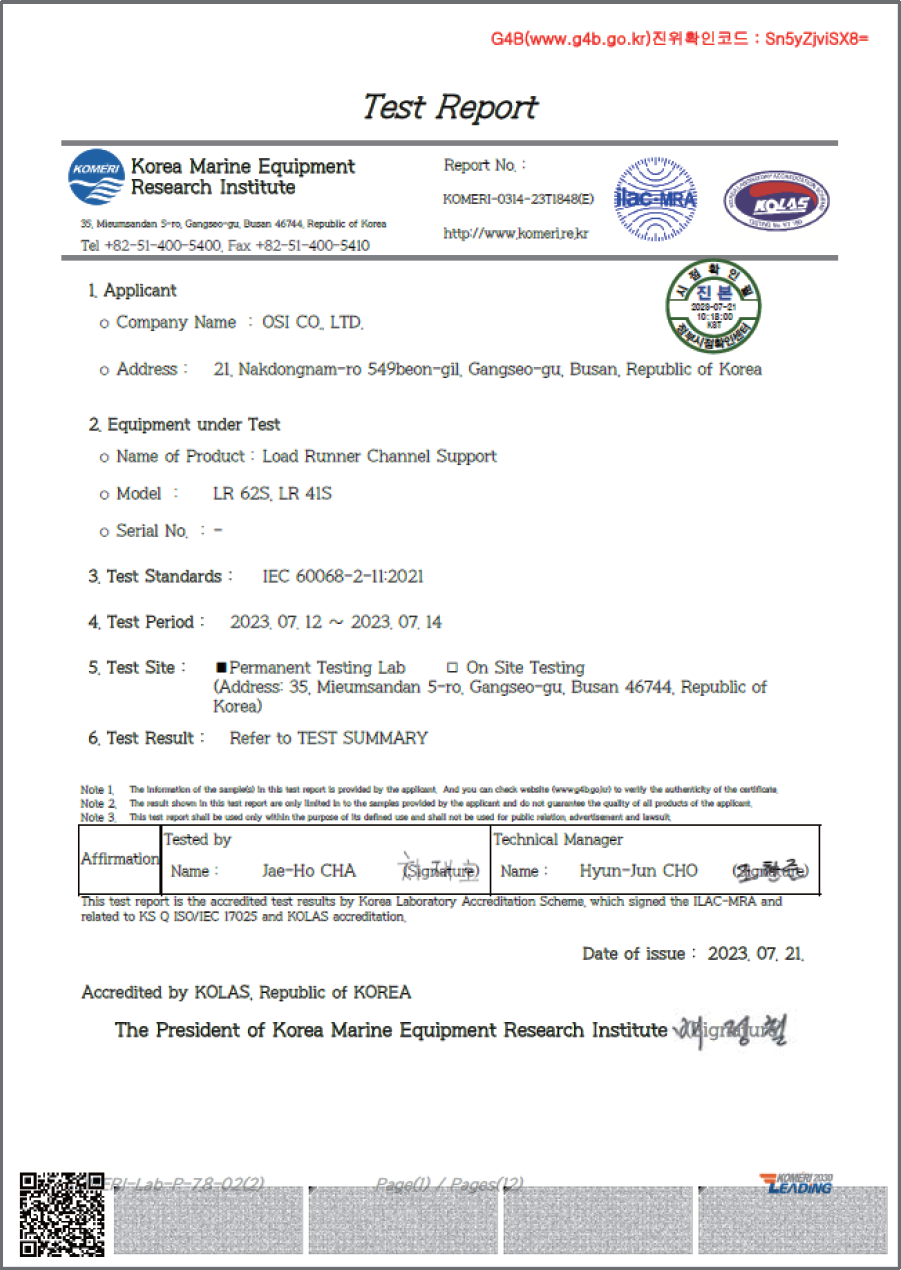

KOMERI(Korea Marine Equipment Research Institute) Test Report

KOMERI(Korea Marine Equipment Research Institute) Test Report

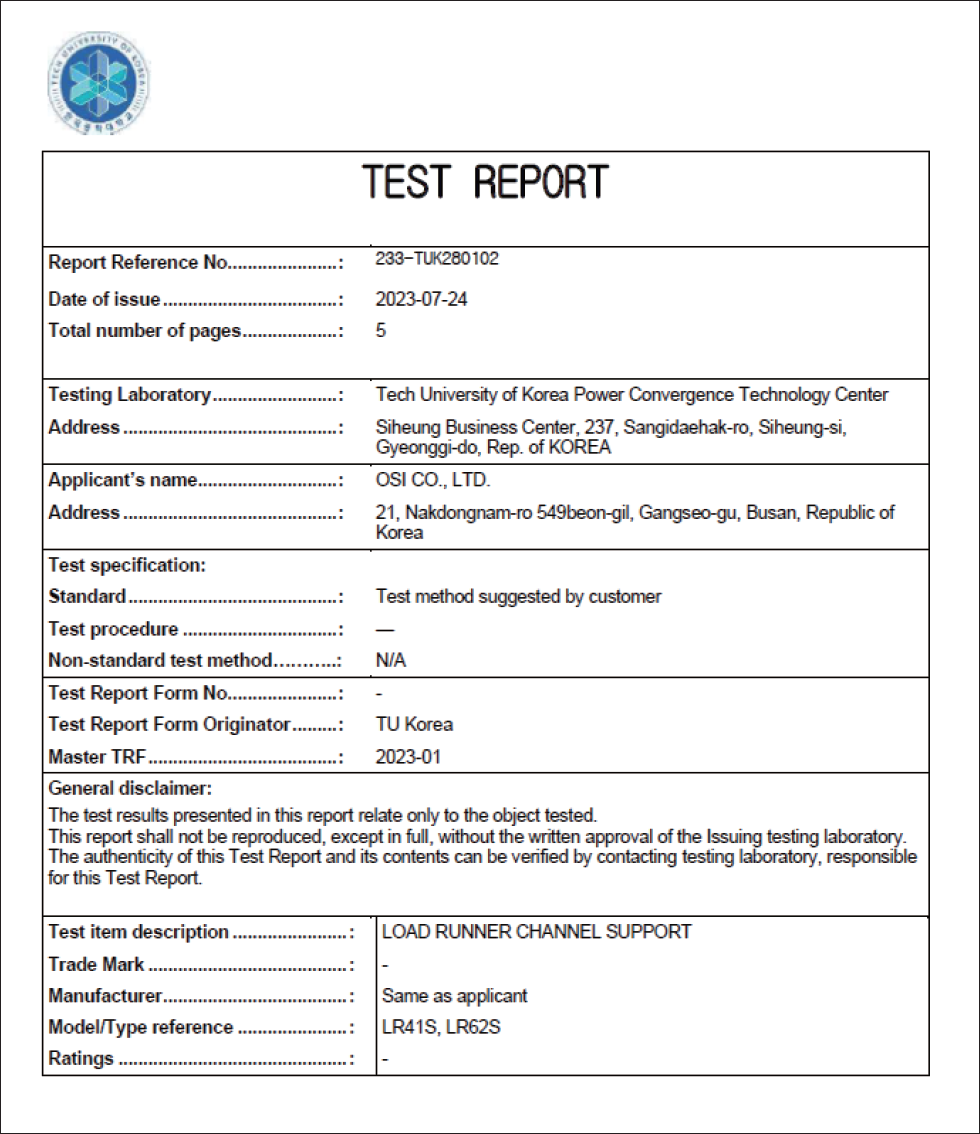

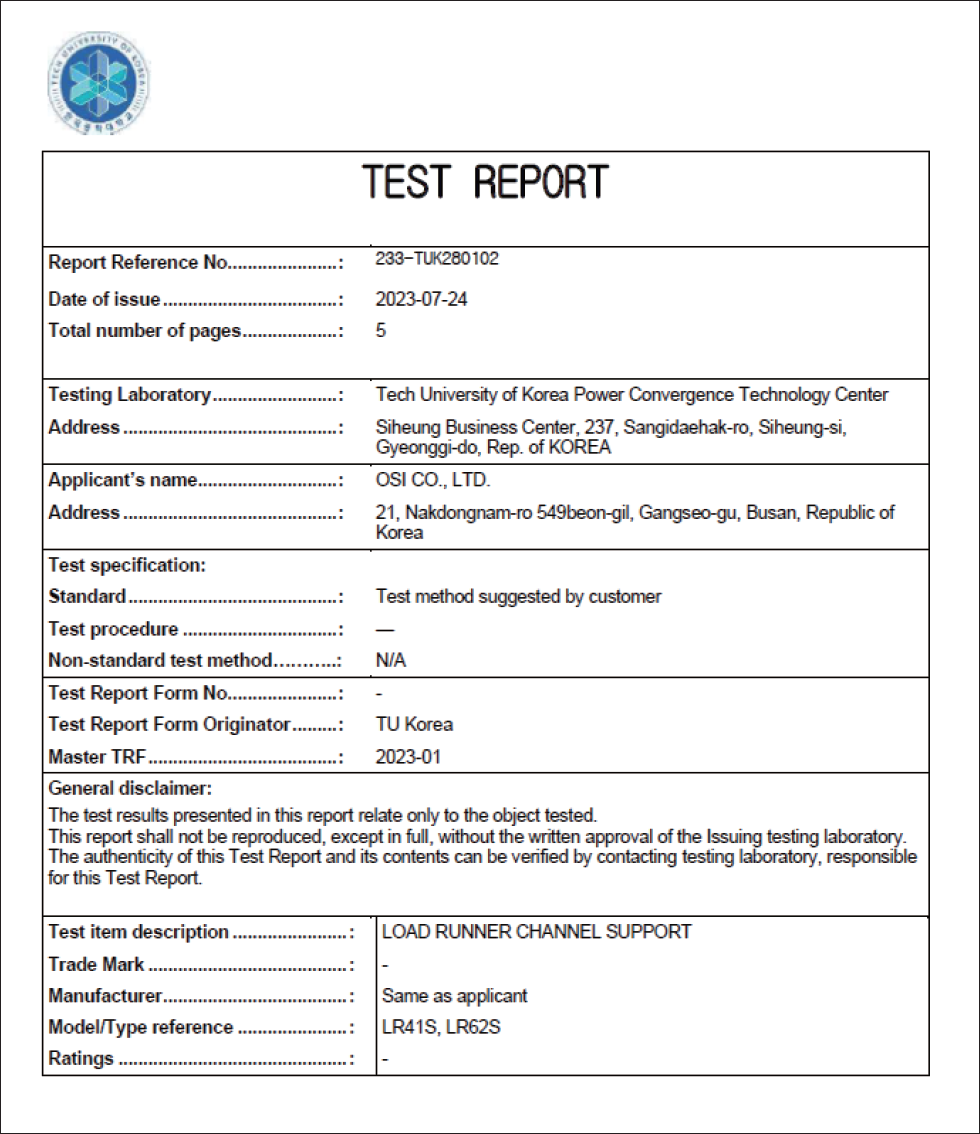

Tech University of Korea Power Convergence Technology Center - Test Report

Tech University of Korea Power Convergence Technology Center - Test Report

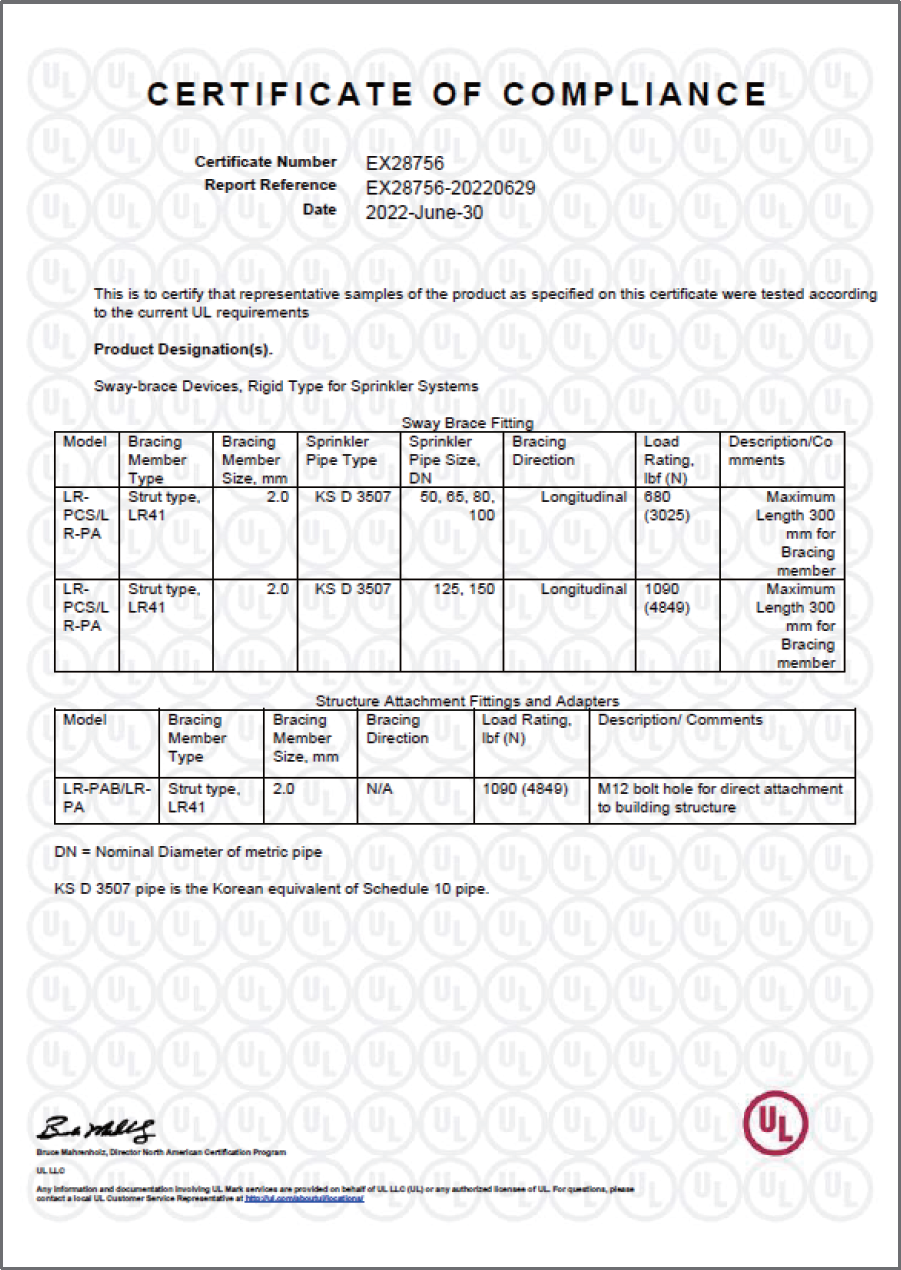

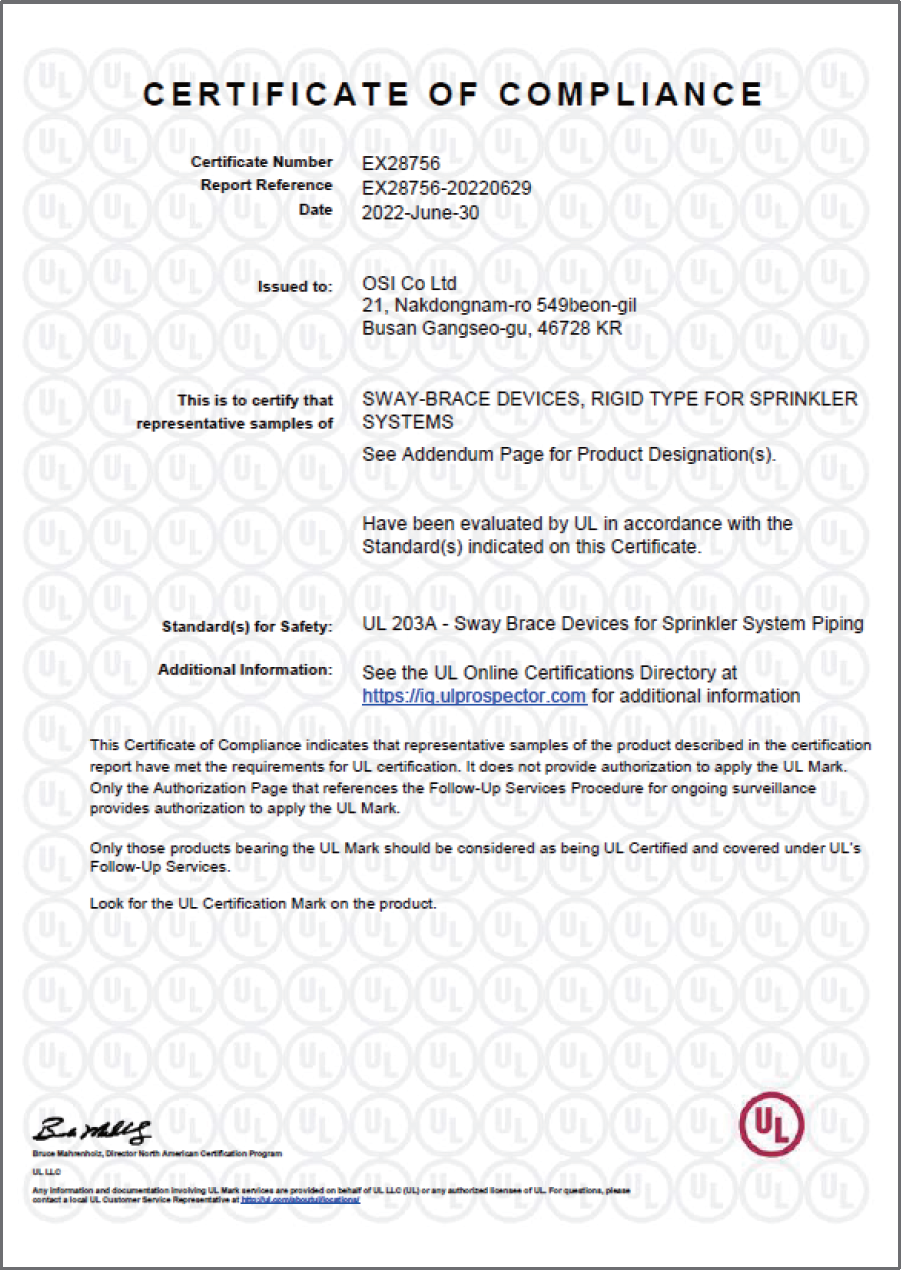

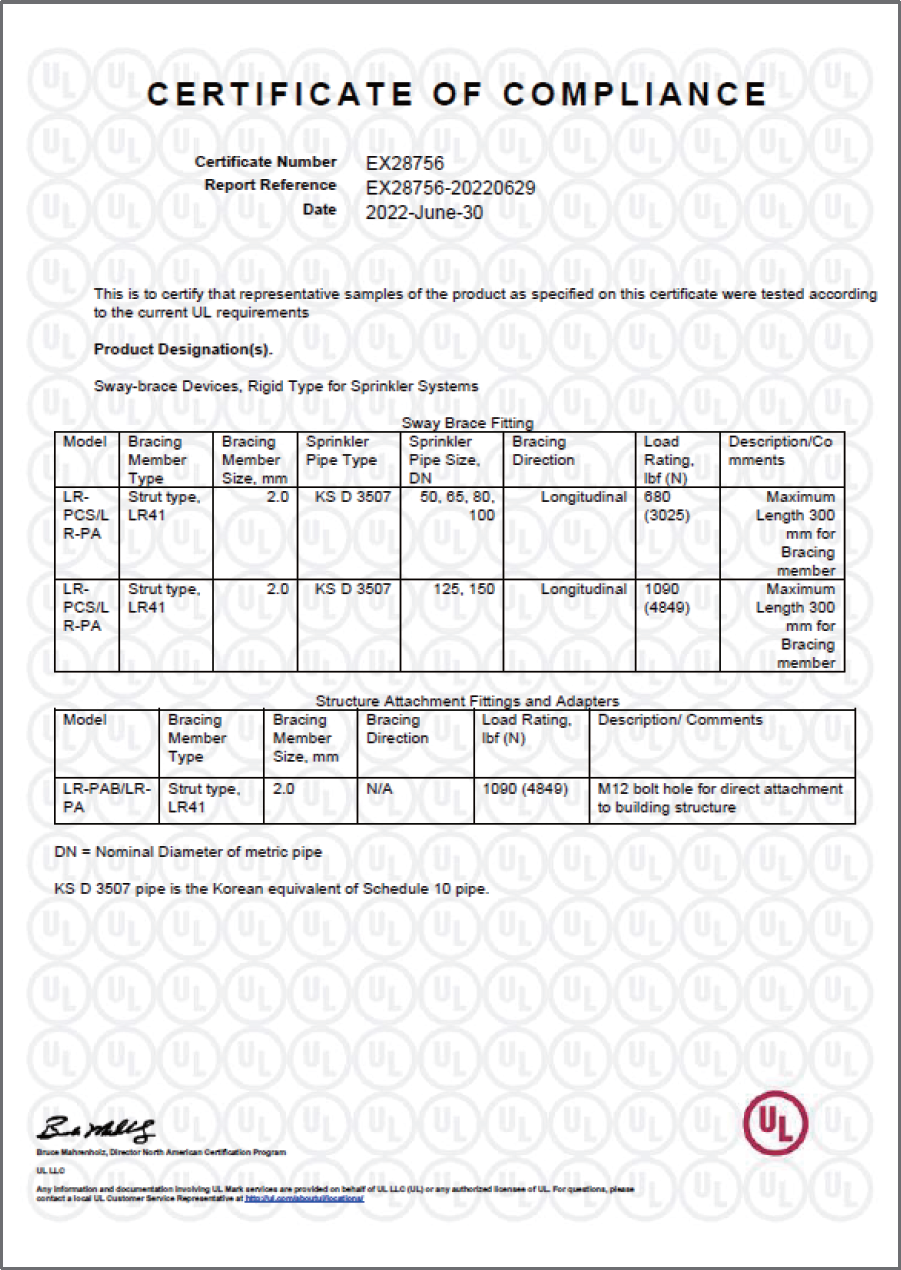

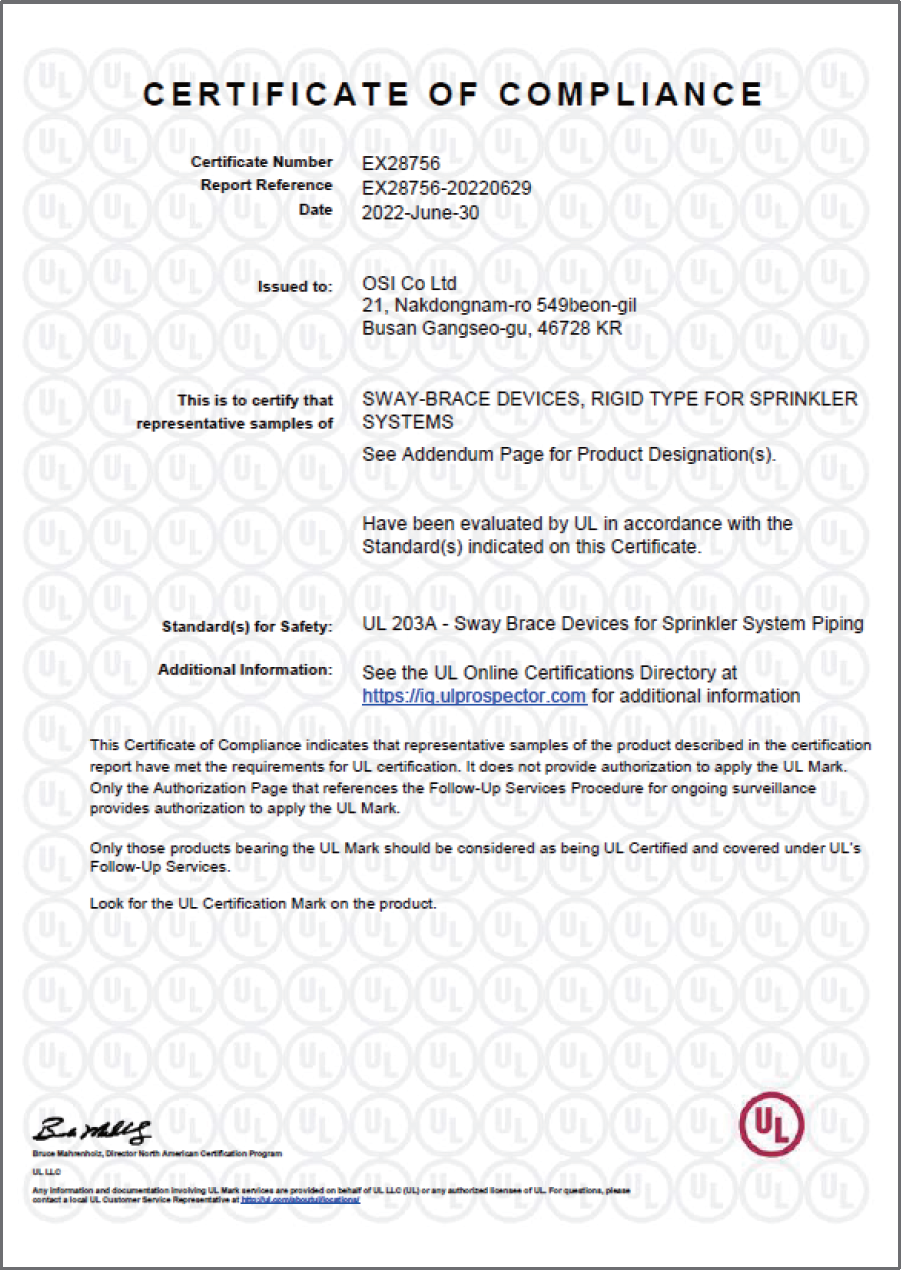

UL(An Affiliated of Underwriters Laboratories Inc.) Certificate of Compliance

UL(An Affiliated of Underwriters Laboratories Inc.) Certificate of Compliance

↑ Top

Company

Overview

Company

Overview  Environment & Smart Modular system

Environment & Smart Modular system

Yangju

Yangju

PosMAC 3.0 Corrosion resistance of sheared edge

When a sheared edge occurs, the upper plating layer melts to cover the cross-section and promotes the growth of

stable corrosion products. However, red rust will occur on the already exposed steel plate. After that, if the sheared

edge is coated with a film of corrosion products, it prevents the corrosion of the cross section.

PosMAC 3.0 Corrosion resistance of sheared edge

When a sheared edge occurs, the upper plating layer melts to cover the cross-section and promotes the growth of

stable corrosion products. However, red rust will occur on the already exposed steel plate. After that, if the sheared

edge is coated with a film of corrosion products, it prevents the corrosion of the cross section.

Galvanizing vs GEOCOTE specification

Electro galvanizing vs Hot dip galvanizing vs Zinc Flake Coating

Galvanizing vs GEOCOTE specification

Electro galvanizing vs Hot dip galvanizing vs Zinc Flake Coating

Galvanizing vs GEOCOTE salt spray

Test per steel grade after applying GEOCOTE

Galvanizing vs GEOCOTE salt spray

Test per steel grade after applying GEOCOTE

Channel Load Table

Channel Load Table

Channel Load Table

Channel Load Table

Channel Load Table

Channel Load Table

Korea Conformity Laboratories Test Report

Korea Conformity Laboratories Test Report

KTL(Korea Testing Laboratory) Test Report

KTL(Korea Testing Laboratory) Test Report

KOMERI(Korea Marine Equipment Research Institute) Test Report

KOMERI(Korea Marine Equipment Research Institute) Test Report

Tech University of Korea Power Convergence Technology Center - Test Report

Tech University of Korea Power Convergence Technology Center - Test Report

UL(An Affiliated of Underwriters Laboratories Inc.) Certificate of Compliance

UL(An Affiliated of Underwriters Laboratories Inc.) Certificate of Compliance